For Fernway, packaging isn’t just a vessel for cannabis products—it’s a reflection of the brand’s identity and its promise of quality and care. Founded in 2019 by four friends in Massachusetts, Fernway has grown rapidly, expanding into New Jersey, New York, and Illinois. But with each new market comes a new set of labeling and regulatory hurdles.

“Every time we enter a new market, we do a regulatory analysis under the lens of packaging,” says Kevin Wu, Fernway’s COO and co-founder. “The goal is to make one carton or pack fit as many states’ regulations as possible.” Each state dictates its own rules for THC potency data, batch labeling, expiration dates, and even illustrations. “For example, Illinois doesn’t allow images of fruit on cannabis packaging [to avoid being mistaken for candy by children], so we replaced our strawberry illustrations with drawings of ferns.”

Navigating that patchwork of rules became a logistical and operational challenge. But the bigger strain came from the labeling process itself.

From hand application to automated precision

Before automation, Fernway’s operators printed regulatory labels on Epson printers, loaded them onto manual dispensers, and applied each one by hand. That meant roughly one carton per minute—far too slow for a company scaling into multiple states.

“The human hands can only work so fast,” says Wu. “It wasn’t a big deal when we were selling a few thousand units a month, but once that turned into tens of thousands, it became unsustainable.”

Label accuracy was another pain point. “Having a premium brand means the product has to look the part,” Wu adds. “It’s hard to pull that off when the label is crooked or hanging off the edge of the box.”

That’s when Fernway turned to Paxiom for a more scalable solution. The company purchased its first dual-head carton labeler in 2022 for Massachusetts, then followed with additional units for New Jersey, Illinois, and New York as new facilities came online. A fifth system is planned for early 2026.

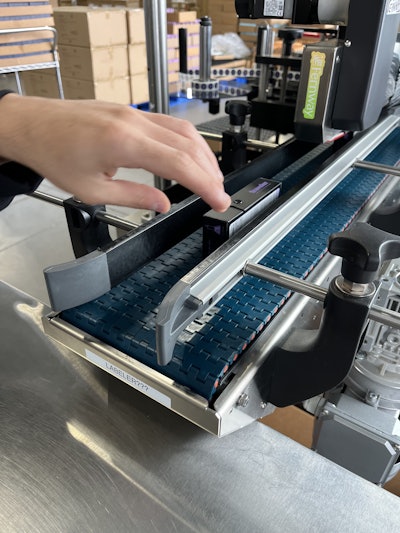

Paxiom’s two-headed carton labeler applies labels to two sides of a carton at up to 30 to 40 cartons per minute, a roughly 30x improvement over hand labeling. Operators feed cartons onto a conveyor manually, and as they move through the machine, each label head applies one of two labels in sequence—typically a front-facing regulatory label and a secondary back label for marketing copy, QR codes, or batch details.

The system features a stainless-steel frame, a split-belt conveyor with product guides, and a photo cell start/stop sensor to ensure precise timing and label placement.

“It’s accurate, fast, and flexible,” says Wu. “We even reduced the footprint of our packaging by 30% without having to modify the equipment. We just created new programs and recipes.”

Wu also praised the ease of training and changeover. “After a few weeks, someone can go from zero to fully understanding not just how to use the machine but also how to troubleshoot and reprogram it for different box sizes,” he says. “That’s critical for us because we’re constantly changing over—sometimes every thousand or two thousand cartons.” The stainless steel, split-belt conveyor system provides precise control for consistent label placement.Fernway

The stainless steel, split-belt conveyor system provides precise control for consistent label placement.Fernway

Managing the data behind the label

The variable data printed on each Fernway label is drawn from test results uploaded by independent labs to a platform called Confident Cannabis, then integrated into the company’s Acumatica ERP system. That ensures the correct batch data—THC content, potency, lot number, and expiration date—flows seamlessly to each label. “Having the right software to manage all that data has been huge,” Wu says. “It’s what keeps us compliant across states.”

With automation, that data integrity now extends to the physical label application. The Paxiom equipment provides not just speed and precision, but consistency that human operators couldn’t match. “Occasionally we’d find a missing label or one upside down,” Wu says. “Those were experiences we just couldn’t afford to have.”

Training and support

Each new machine installation is supported by an on-site Paxiom technician, who commissions the equipment and provides hands-on training. “They stay a couple of days to work with our team and make sure we’re comfortable running changeovers, handling maintenance, and troubleshooting,” Wu says. “By the time we got to our third and fourth machines, the process was seamless. Our technicians were already familiar with the workflows.”

Fernway’s labeling cells are currently semi-automated—the cartons are hand-fed into the machine and case-packed manually after labeling—but Wu says the company is now exploring downstream automation with Paxiom to extend those gains further. “We’d love to fully automate everything,” he says, “but because every state requires its own facility, each investment gets multiplied across multiple locations.”

Even with those constraints, the investment in automation has paid off. “The payback has been roughly a year,” says Wu. “That’s equivalent to about two technicians’ worth of labor. It allows us to stay lean, give our team job security, and let them focus on higher-value work.” Fernway’s premium rigid cartons, used for edibles and vaporizer products, now carry consistent, compliant labeling in Massachusetts, New Jersey, Illinois, and New York.Fernway

Fernway’s premium rigid cartons, used for edibles and vaporizer products, now carry consistent, compliant labeling in Massachusetts, New Jersey, Illinois, and New York.Fernway

Thinking beyond the consumer

Wu offers a piece of advice that applies to cannabis brands and CPGs alike: when designing packaging, think about the entire supply chain, not just the consumer experience.

“When we first designed our box, we were thinking only about our brand and the end consumer,” he says. “What we didn’t do was talk to our dispensary partners, and that was a mistake.”

Dispensaries in Massachusetts and New Jersey, for example, urged Fernway to reduce its package size to fit more inventory in limited vault space. “That feedback led us to cut our carton footprint by 30%,” Wu says. “It was a lesson in remembering that our ‘customer’ isn’t just the person who opens the box—it’s everyone who touches it along the way: transporters, dispensary staff, budtenders, and finally the consumer.”

For Fernway, packaging is both a brand expression and an operational necessity. And by investing in automation, the company is proving that even in a fragmented, heavily regulated market, consistency and quality can still scale.

Machine at a Glance

Equipment: Paxiom Two-Head Carton Labeler

Application: Applies labels to two sides of Fernway’s rigid paperboard cartons

Speed: Up to 30–40 cartons per minute

Operation: Cartons are hand-fed and discharged manually

Features: Stainless steel frame, compact footprint, split-belt conveyor with product guides, photo cell for timing, micro-regulation adjustments for label head positioning, and adjustable anti-vibration feet

Commissioning: On-site setup and operator training provided by Paxiom technicians

Performance: Replaced manual labeling (~1 carton/min) with automated throughput of up to 40 cartons/min; payback in approximately one year