This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

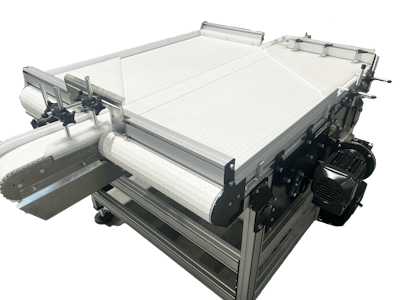

Columbus McKinnon Corporation business Garvey is excited to launch a new product line in addition to the Garvey portfolio, the Aluminum Bi-FloTM accumulation table.

Garvey is a recognized expert in conveying, accumulation, and automation solutions for several industries including food & beverage, pharmaceutical, material handling, and more.

The Aluminum Bi-FloTM from Garvey provides a unique tool to manufacturers that allows for optimized product accumulation and product movement, eliminating bottlenecks in operations to boost overall throughput and efficiencies by maximizing line uptime.

Designed for compactness and efficiency, the Aluminum Bi-FloTM utilizes a single motor which drives three modular chain sets in different directions, enabling product recirculation in a small footprint. The design is simple, robust, energy-efficient, and easy to integrate into existing lines. One of the key design elements is moving from a stainless-steel frame of the original Bi-FloTM to the aluminum frame in this new version. This update offers tremendous cost savings and opens Garvey’s accumulation technology to applications that don’t require any washdown capabilities.

Companies looking to achieve lean manufacturing can consider the Aluminum Bi-FloTM as a key reducer of energy and space in your factory. Due to its low motor count, this accumulation table provides a notable energy cost difference compared to other accumulation technologies.

This product offers three different configuration options depending on your application, such as one outfeed lane which is used for applications where product needs to be introduced to a line in a single file from a station receiving bulk product. Another option is one infeed lane, used for applications where an end of line is reached, and the output of product is an inconsistent flow rate. End of line accumulation prevents line backups and shutdowns due to inconsistent flow rates. Finally, the one infeed and one outfeed configuration is used as an accumulation station to balance a production line and prevent upstream equipment from shutting down while maintaining maximum throughput at each machine.

Other features that the Aluminum Bi-FloTM offers manufacturers include:

· Optimized Product Transfer: Flush side in/outfeeds enable stable side transfers. Optional nosebar configurations are available for tight spaces.

· Customizable Dimension: Width and length can be tailored to fit available space and accumulation needs.

· Flexible Motor Placement: Motor can be mounted on either side for easier integration

· Controlled Flow: Optional manual or automatic gates manage infeed and outfeed flow.

· Durable & Lightweight Construction: Aluminum frame offers high load capacity with cost-effective rigidity.

· Multi-Line Integration: Supports multiple infeed/outfeed setups to merge or split product flow across lines.

· Versatile Product Handling: Compatible with round, oval, and rectangular products.

· Safe Operation: Pinch-free design ensures safe manual interaction near or on the table.