In this episode of Package This, we explore the world of feeding and inserting equipment on packaging lines. These crucial machines ensure products, components, and containers are staged and ready for the packaging process. Discover pick-and-place systems, friction feeders, orienting and unscrambling machines, vibratory feeders, protective packaging feeders, and hanger applicators. Join us as we delve into the technologies and solutions that streamline packaging operations, enhance efficiency, and reduce labor costs for brands.

Welcome back to Package This, your guide to the world of packaging machinery.

Today, we’re diving into feeding and inserting equipment—the often-overlooked packaging machines that stage products, components, and containers for the next step in the packaging process.

These machines are all about precision and timing. From placing cookies into trays to lining up bottles for filling, they’re key to smooth, high-speed operation.

Pick-and-Place Systems

Let’s get into it—starting with pick-and-place systems. These machines combine the use of robots—like delta or SCARA arms—and vision systems to grab items from a conveyor and load them into packaging.

Think sandwich cookies placed into trays, or chip bags loaded into cases—automatically, quickly, and with no human handoffs.

Gentle grippers at the end of each robotic arm let them handle all kinds of products, delivering serious speed, accuracy, and consistency on your packaging line.

Orienting & Unscrambling

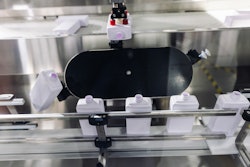

Now, let’s talk about getting things lined up. On high-speed filling lines, empty bottles are often dumped randomly prior to filling. Unscramblers fix that by spinning, flipping, or sliding them into the correct orientation.

Once lined up with their mouths facing upward, they’re ready for filling, capping, or labeling. It’s all about flow, so no jams and no stops. Just smooth sailing down the line.

Placement & Feeder Systems

Next up: placement and feeder systems. These machines place or insert items into or onto packages—think desiccant pouches, instruction manuals, or even promotional flyers.

One common type is the friction feeder, which slides flat items like leaflets or labels into a pack, one at a time, at high speed.

Vibratory Feeders

Need to move small parts like screws or fasteners? That’s where vibratory feeders shine.

They use vibration to move and align parts—like gently shaking screws in a bowl until they’re lined up and ready to be counted into a package. It’s a simple idea that delivers powerful results for packaging home goods and organizing packaging components like caps for bottles.

Protective Packaging Feeders

What about keeping products safe in transit?

Protective packaging feeders insert cushioning materials—like air pillows or paper fill—into boxes before sealing. These systems inflate and cut on the fly to fit just right, helping prevent damage during shipping.

Hanger Applicators

Last but not least: hanger applicators are the machines that apply hang tabs to packages for retail display.

They peel adhesive-backed tabs from a sheet and place them precisely on each package so it hangs neatly in store aisles. With this equipment, it’s all about small details and big impact.

From placing products to prepping them for shelves or shipping, feeding and inserting equipment solves big problems for brands, one package at a time.

Thanks for watching this episode on feeding and inserting equipment – we hope you learned something new! For more videos on packaging equipment and materials, subscribe to Packaging World’s Youtube channel and get all of the videos in the Package This series.

And if you’re shopping for feeding and inserting equipment, or any other type of packaging equipment, visit PMMI ProSource at ProSource.org, a searchable directory with over 1,000 packaging and processing suppliers.

Until next time, keep on packaging!