Automation can improve compliance with the Food Safety Modernization Act (FSMA). Here are some tips from food company managers that may help you improve your own technology choices:

1. Lock it down. Design and install food safety systems that are locked down to prevent human bypass and that navigate through garbage-in, garbage-out temptations while remaining extremely user friendly.

2. Give operators the right tools. Food safety often hinges on the proficiency of operators and other plant-floor personnel to work efficiently with equipment. Well-written procedural documentation is an invaluable teaching aid in compliance as well as productivity. Likewise, all automation should be user friendly, from controls to software and recordkeeping systems.

3. Involve QA/QC. Involve quality personnel (and others) in engineering reviews and meetings. They may catch something engineers, operations, and maintenance personnel on a project team might miss.

4. Verification is critical. The “CCP” in Hazard Analysis & Critical Control Points (HACCP) is critical. Establish standard operating procedures and at least a double control system that can verify any products before they leave the production line. You will need enough inventory to keep the products in a safe place and will need to wait for all testing to be confirmed before selling the product.

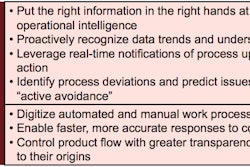

5. Track from origin through distribution. FSMA requires food companies to follow products from the origin of their raw materials through finished product distribution. In addition to using non-automated tactics, sensors can be a convenient way to track critical raw materials from point of origin through loading and transportation. Manufacturing processes require the most continuous analysis possible; technology now affords the same capability outside the plant.

6. Calibrate manually: Sensors should be calibrated with sufficient frequency, and if there is any doubt regarding their accuracy, they should be calibrated manually—not just with a field calibrator’s “auto” mode. Trust in the reliability of sensor data led one survey respondent to engineer “bio-growth” tracking routines to ensure product was processed and packaged before it posed a risk and had to be scrapped. Another food company executive is seeking to expand the reach of sensor data upward from plant networks to “deliver data to the plant ERP system for trend analysis.”

7. Real-time test results. To improve execution accuracy, implement real-time input for food safety test results and on-floor checklists, all of which should be stored in a central database that is accessible to quality assurance, production management, and supervisory personnel.

8. Let your budget be your guide. There are limits to how cutting-edge a technology investment must be. As one food plant pro explains, “New innovations can be very difficult and expensive to properly retrofit to comply with rules.”

Find additional, related information in the Automation World Batch Process Playbook.

Liked this article? Download the entire Food Safety Playbook here.

1. Lock it down. 2. Give operators the right tools.3. Involve QA/QC.

4. Verification is critical. The “CCP” in Hazard Analysis & Critical Control Points (HACCP) is critical. Establish standard operating procedures and at least a double control system that can verify any products before they leave the production line. You will need enough inventory to keep the products in a safe place and will need to wait for all testing to be confirmed before selling the product.

5. Track from origin through distribution. FSMA requires food companies to follow products from the origin of their raw materials through finished product distribution. In addition to using non-automated tactics, sensors can be a convenient way to track critical raw materials from point of origin through loading and transportation. Manufacturing processes require the most continuous analysis possible; technology now affords the same capability outside the plant.

6. Calibrate manually: Sensors should be calibrated with sufficient frequency, and if there is any doubt regarding their accuracy, they should be calibrated manually—not just with a field calibrator’s “auto” mode. Trust in the reliability of sensor data led one survey respondent to engineer “bio-growth” tracking routines to ensure product was processed and packaged before it posed a risk and had to be scrapped. Another food company executive is seeking to expand the reach of sensor data upward from plant networks to “deliver data to the plant ERP system for trend analysis.”

7. Real-time test results. To improve execution accuracy, implement real-time input for food safety test results and on-floor checklists, all of which should be stored in a central database that is accessible to quality assurance, production management, and supervisory personnel.

8. Let your budget be your guide. There are limits to how cutting-edge a technology investment must be. As one food plant pro explains, “New innovations can be very difficult and expensive to properly retrofit to comply with rules.”

Find additional, related information in the Automation World Batch Process Playbook.

Liked this article? Download the entire Food Safety Playbook here.

5. Track from origin through distribution. FSMA requires food companies to follow products from the origin of their raw materials through finished product distribution. In addition to using non-automated tactics, sensors can be a convenient way to track critical raw materials from point of origin through loading and transportation. Manufacturing processes require the most continuous analysis possible; technology now affords the same capability outside the plant.

6. Calibrate manually: Sensors should be calibrated with sufficient frequency, and if there is any doubt regarding their accuracy, they should be calibrated manually—not just with a field calibrator’s “auto” mode. Trust in the reliability of sensor data led one survey respondent to engineer “bio-growth” tracking routines to ensure product was processed and packaged before it posed a risk and had to be scrapped. Another food company executive is seeking to expand the reach of sensor data upward from plant networks to “deliver data to the plant ERP system for trend analysis.”

7. Real-time test results. To improve execution accuracy, implement real-time input for food safety test results and on-floor checklists, all of which should be stored in a central database that is accessible to quality assurance, production management, and supervisory personnel.

8. Let your budget be your guide. There are limits to how cutting-edge a technology investment must be. As one food plant pro explains, “New innovations can be very difficult and expensive to properly retrofit to comply with rules.”

Find additional, related information in the Automation World Batch Process Playbook.

Liked this article? Download the entire Food Safety Playbook here.

5. Track from origin through distribution. 6. Calibrate manually: 7. Real-time test results.8. Let your budget be your guide. Find additional, related information in the Automation World Batch Process Playbook.Liked this article? Download the entire Food Safety Playbook here.