With nearly 60% of all food and beverage companies having been affected by a recall in the last five years, improving food safety is more imperative than ever for food and beverage manufacturers. In this era of heightened awareness of food safety issues and increasing regulations, the focus has shifted from reacting to recalls to preventing them.

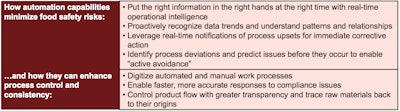

It’s critical to gain better visibility and deep insights across operations to improve food safety and quality. Leveraging the power of the Industrial Internet, manufacturers need to take a holistic approach by connecting their machines, data, insights, and people to deliver real- time operational intelligence. With the right information at hand, they can build a safer, more profitable food production environment.

Prevention begins with a comprehensive approach that targets risks and ensures food safety through five key software capabilities: real-time operational intelligence; trending capabilities; rich analytics; electronic standard work practices; and powerful traceability.

1. Enable anywhere, anytime decision making

In today’s mobile environment, it’s imperative to deliver relevant information to operators and other key decision makers wherever they are. Whether they’re on the plant floor or offsite, the ability to receive real-time information and notifications through a mobile device such as an iPad or smartphone enables them to respond immediately to critical events— increasing productivity and minimizing the risk of safety mishaps. Software can make sense of the complexity of data in today’s plants and speed decision-making by putting the right, contextualized information in the right hands, based on role and location.

2. Eliminate the root cause of product risk

At the heart of preventing recalls is the ability to proactively recognize production trends as they happen and take immediate corrective action as needed. Instead of looking solely at historical data, plant managers today can view real-time production information to perform root-cause analysis and take corrective actions instantaneously. For example, temperature trending analysis led one food manufacturer to discover inconsistent oven temperatures. Operators were able to adjust the ovens “on the fly” to compensate for the temperature drifts, thereby ensuring food quality and safety.

Understanding patterns and relationships between various sets of data such as temperatures, speeds, pH levels, and humidity—rather than compartmentalizing potentially at-risk products using post-production testing—can help eliminate the true root cause of product risk.

3. Prevent quality issues with predictive analytics

Real-time predictive analytics can provide critical decision support to foresee issues before an event occurs. Advanced software with predictive analytics may leverage robust modeling engines and multivariate analysis to preempt alarm and failure events based on historical models—enabling “active avoidance.”

For example, if high pH levels can compromise product quality and safety, and the level starts deviating toward a critical condition, predictive analytics can, in real-time, prevent a critical condition from occurring. One U.S. dairy, for instance, used this technology to improve process control and reduce spoilage in dry baby formula through better real-time analysis of moisture content, drying time, and other parameters.

4. Minimize inconsistencies with standard work processes

Food safety Standard Operating Procedures (SOPs) are a key element to ensure that operators consistently adhere to recipes and comply with Hazard Analysis & Critical Control Points (HACCP) programs. The latest workflow software enables manufacturers to digitize manual and automated work processes instead of relying on static paper trails or a binder at an operator station.

Automating SOPs with step-by-step operator instructions provides greater precision and fewer errors. It also provides validated data entry; data capture for analysis and historical records; and automated HACCP management by integrating production work processes with real-time HACCP testing for faster response to compliance issues.

5. Enable tighter controls across the supply chain with traceability

Rather than merely minimizing the impact of recalls after they occur, manufacturers today can use software traceability information to improve food safety and virtually prevent recalls. The latest software systems enable product tracing throughout every step of the manufacturing process to identify the product’s exact materials and quality characteristics, control the flow of product between equipment, and manage in-process inventories in real time.

Such systems can be used to integrate all data and trace complex batches, continuous processes, sub-processes, components, or byproducts to determine the origin and destination of all incoming materials and outgoing finished goods. By tracing raw materials to finished product, you can establish tighter controls to safeguard the supply chain.

Why integrate

With prevention as the core goal, each of the five critical software capabilities discussed plays a distinct role in minimizing food safety risk. Leveraging all five capabilities—as opposed

to one or a select few—provides the greatest advantage, because the insight gained from each critical capability becomes exponentially more powerful as it builds on the intelligence provided by the others.

An integrated, plant-wide approach provides the deep facility-wide insight to help operators predict when issues are likely to occur, and take real-time corrective action when the process digresses from specifications. This ensures consistently high quality and food safety, which in turn, drives greater operational productivity.

1. Enable anywhere, anytime decision making

In today’s mobile environment, it’s imperative to deliver relevant information to operators and other key decision makers wherever they are. Whether they’re on the plant floor or offsite, the ability to receive real-time information and notifications through a mobile device such as an iPad or smartphone enables them to respond immediately to critical events— increasing productivity and minimizing the risk of safety mishaps. Software can make sense of the complexity of data in today’s plants and speed decision-making by putting the right, contextualized information in the right hands, based on role and location.

2. Eliminate the root cause of product risk

At the heart of preventing recalls is the ability to proactively recognize production trends as they happen and take immediate corrective action as needed. Instead of looking solely at historical data, plant managers today can view real-time production information to perform root-cause analysis and take corrective actions instantaneously. For example, temperature trending analysis led one food manufacturer to discover inconsistent oven temperatures. Operators were able to adjust the ovens “on the fly” to compensate for the temperature drifts, thereby ensuring food quality and safety.

Understanding patterns and relationships between various sets of data such as temperatures, speeds, pH levels, and humidity—rather than compartmentalizing potentially at-risk products using post-production testing—can help eliminate the true root cause of product risk.

1. Enable anywhere, anytime decision making

2. Eliminate the root cause of product risk

At the heart of preventing recalls is the ability to proactively recognize production trends as they happen and take immediate corrective action as needed. Instead of looking solely at historical data, plant managers today can view real-time production information to perform root-cause analysis and take corrective actions instantaneously. For example, temperature trending analysis led one food manufacturer to discover inconsistent oven temperatures. Operators were able to adjust the ovens “on the fly” to compensate for the temperature drifts, thereby ensuring food quality and safety.

Understanding patterns and relationships between various sets of data such as temperatures, speeds, pH levels, and humidity—rather than compartmentalizing potentially at-risk products using post-production testing—can help eliminate the true root cause of product risk.

2. Eliminate the root cause of product risk3. Prevent quality issues with predictive analytics

4. Minimize inconsistencies with standard work processes

Food safety Standard Operating Procedures (SOPs) are a key element to ensure that operators consistently adhere to recipes and comply with Hazard Analysis & Critical Control Points (HACCP) programs. The latest workflow software enables manufacturers to digitize manual and automated work processes instead of relying on static paper trails or a binder at an operator station.

Automating SOPs with step-by-step operator instructions provides greater precision and fewer errors. It also provides validated data entry; data capture for analysis and historical records; and automated HACCP management by integrating production work processes with real-time HACCP testing for faster response to compliance issues.

5. Enable tighter controls across the supply chain with traceability

Rather than merely minimizing the impact of recalls after they occur, manufacturers today can use software traceability information to improve food safety and virtually prevent recalls. The latest software systems enable product tracing throughout every step of the manufacturing process to identify the product’s exact materials and quality characteristics, control the flow of product between equipment, and manage in-process inventories in real time.

Such systems can be used to integrate all data and trace complex batches, continuous processes, sub-processes, components, or byproducts to determine the origin and destination of all incoming materials and outgoing finished goods. By tracing raw materials to finished product, you can establish tighter controls to safeguard the supply chain.

4. Minimize inconsistencies with standard work processes

5. Enable tighter controls across the supply chain with traceability

Rather than merely minimizing the impact of recalls after they occur, manufacturers today can use software traceability information to improve food safety and virtually prevent recalls. The latest software systems enable product tracing throughout every step of the manufacturing process to identify the product’s exact materials and quality characteristics, control the flow of product between equipment, and manage in-process inventories in real time.

Such systems can be used to integrate all data and trace complex batches, continuous processes, sub-processes, components, or byproducts to determine the origin and destination of all incoming materials and outgoing finished goods. By tracing raw materials to finished product, you can establish tighter controls to safeguard the supply chain.

5. Enable tighter controls across the supply chain with traceabilityWhy integrateThis article is excerpted and adapted from information supplied by GE Intelligent Platforms.Liked this article? Download the entire Food Safety Playbook here.