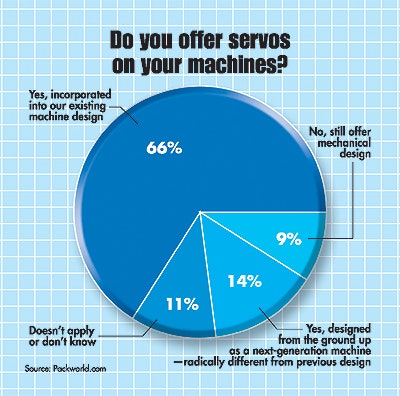

In a recent survey of machine builders, 80% of machine builders indicated they’re using servo technology in their machines. But only 14% indicated they’re using servos in machines that have been designed from the ground up around the technology.

Many experts believe that only machines designed from scratch based on servo technology—so-called third-generation servo-based packaging machines—are really poised to extract the full benefit that the technology promises.

Among the suvey’s most revealing findings is that 64% of respondents believed that servos increase the overall cost of packaging equipment. Advocates of servo technology believe the opposite is true. It is true that servo drives and motors are more expensive than their AC drive and motor counterparts. But advocates say when applied in a third-generation machine, servos can eliminate a great number of mechanical components, such as shafts, gearboxes, chains, and sprockets, resulting in a lower overall cost. Although 14% of the machine builder respondents found this to be true, most machine builders had yet to experience this.

A cross-tabulation of the two questions revealed that 76% of machine builders who have added servos to existing designs also believe the servos increase the overall cost of the machine. That makes sense—such machines would be more costly to make because mechanical components are still being used in their designs.

But what’s surprising is that of those machine builders who are using servos on totally new machine designs, 64% still believe servos increase the overall cost of the machine.

The survey reveals a divide between what advocates of servo technology believe—that third-generation servo-based packaging machinery can be cheaper, better, and faster (see www.pack- world.com/go/c053)—and what packaging machine builders have experienced.

The survey, which was conducted on Packworld.com this summer in cooperation with Control Design magazine, was restricted solely to machine builders. It drew 56 qualified responses, primarily from those who work in sales and marketing or engineering capacities.

See sidebar to this article: Are servos worth it?

See sidebar to this article: Challenges of servos