Extended Producer Responsibility (EPR) for packaging is officially underway. Producer registration has closed in multiple states, fee schedules are taking shape, and many brands have filed their first packaging reports, while others are still scrambling to get systems and data in place.

At the time of the 2025 Packaging Recycling Summit held by Packaging World magazine in Dallas in June, Oregon was just days away from launching the first operational EPR program for paper and packaging in the U.S., moving from years of planning to implementation.

“We completed the registration and reporting process in Oregon, and we’re really impressed and proud of the work that the producers did,” shared Jeff Fielkow, CEO of the Circular Action Alliance (CAA), at the Summit. CAA is the Producer Responsibility Organization (PRO) selected by five EPR states. “Are we one-hundred percent? No, but more than 2,000 producers have registered for Oregon, and they now have their invoices in their hands.”

In other EPR news, Fielkow noted that Colorado’s registration had closed, with reports due by the end of July, while Minnesota’s deadline was right around the corner.

| Watch this related video, “Live from Product Stewardship Institute's Forum: Dylan de Thomas on Laws Going Live, Key Deadlines, and Industry Guidance” |

But meeting the initial registration and reporting deadlines is only the beginning. Fielkow noted that brand owners are still navigating unfamiliar territory, especially when definitions and obligations vary from one state to the next. “How do I know if I’m foodservice? How do I know which covered materials are part of the program?” he said. Many questions remain, especially for those new to EPR. “This was a massive learning curve,” he added. “But for companies doing business internationally, this is not that new. It’s new here, but not new globally.”

Jason Bergquist, VP – US for RecycleMePMMI Media Group

Jason Bergquist, VP – US for RecycleMePMMI Media Group

Jason Bergquist, VP – US of RecycleMe, a division of Reclay StewardEdge, echoed the challenge of navigating differing requirements. In just the first three states—Oregon, Colorado, and California—producers face three sets of definitions, timelines, material lists, and fee structures. “That’s just in the first three states, with more to come,” he said. “And it can be very challenging.”

One key point of confusion is business-to-business packaging. Oregon includes B2B materials, while Colorado does not. For example, a producer of branded shipping boxes or retail bags might be obligated to report them in Oregon, but not in Colorado. “Two very different impacts to the same producer depending on which state they’re selling into,” Bergquist said. Differences in bottle bill coverage and eco-modulation requirements only add to the complexity.

Fielkow described how CAA is trying to at least standardize the experience for producers. “We want to give a harmonized experience for you working in every state that you’re in,” he said. That includes one portal, one team to work with, and a consistent process for reporting and payment. But CAA’s role is implementation, not legislation. “We didn’t write the laws. We’re interpreting and executing them,” he explained.

Participation so far has been strong, though not universal. Fielkow said many producers waited until the final days before the March 31 reporting deadline in Oregon, creating a surge reminiscent of tax season. “About two weeks before that, we probably had about 300 or 400 producers, and I’m like, oh my gosh,” he said. “But in the last hours, it was like a hockey stick.”

Jeff Bezzo, executive director of plastic and packaging sustainability for SC JohnsonPMMI Media Group

Jeff Bezzo, executive director of plastic and packaging sustainability for SC JohnsonPMMI Media Group

Jeff Bezzo, executive director of plastic and packaging sustainability at SC Johnson, shared that while the company was ultimately able to report on time in Oregon, it wasn’t without challenges. “We had great data for legacy brands like Windex and Draino,” he said, “but recent acquisitions required us to go back and weigh packaging, create databases, and confirm reporting obligations across product types.”

Bezzo emphasized that state-level nuances make cross-functional collaboration essential. “We’re asking the same questions over and over with each new state,” he said, referencing differences in coverage for B2B packaging, DTC shipping formats, and refill systems. “It’s unfortunate, but that’s where we are today.”

| Read this related Q&A, “AMERIPEN’s Packaging Policy Update & 2025 Outlook” |

As states refine their plans, producers also face questions about where their packaging ends up and how fees are calculated. End markets must be verified, and not all packaging materials face the same economic or infrastructure realities. Bergquist noted that these local differences affect the fee structure. In Oregon, high recycling costs for glass contributed to higher fees, leading some companies to consider switching to plastic for cost reasons, even when it runs counter to their branding.

Alex Clark, director of solution engineering for SpecrightPMMI Media Group

Alex Clark, director of solution engineering for SpecrightPMMI Media Group

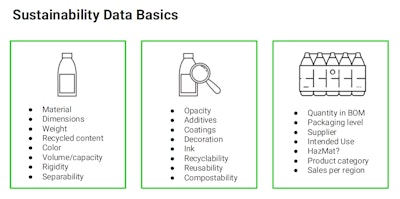

Behind the scenes, many producers are still struggling with data readiness. Said Alex Clark, director of solution engineering for Specright, “Most companies struggle with EPR not because they don’t care, but because they’re struggling to find the right data,” he said.

That’s why Clark urged brands to begin wherever they can, even if it feels small. “Your future self will thank you,” he said.

Specright

Specright

Clark emphasized the need to shift sustainability thinking upstream, integrating it into the early stages of product development rather than treating it as an afterthought. “Instead of thinking about sustainability at the end of the development of a product and how you can report on that, it’s time to start thinking about it at the beginning.”

With more states coming online and reporting cycles repeating annually, brands will need to shift from one-time compliance to continuous improvement. As Bergquist put it, “Try and think big picture. Look at California. Look at Europe. There are areas where there are threads that run through these laws.” The challenge now is pulling those threads into something manageable and making sure producers are ready. PW