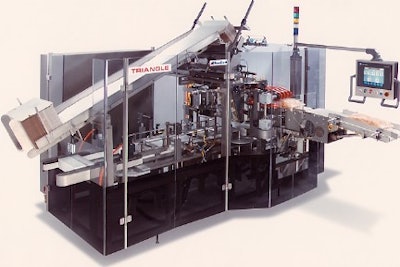

The new technique is said to eliminate jams caused by bags that bunch up or burst during pushed insertions. Bags are propelled, not pushed, into cartons, eliminating product tray, pusher arm, and confiner assemblies. The simplification gives ProLine FC a footprint of 5x10’, which is less than half of a conventional machine.

The cartoner includes advanced technologies such as servo drives, Allen-Bradley ControlLogix™ processor, and Ethernet and DeviceNet communications. It absorbs the output of one single-tube continuous motion bagger and has speeds in excess of 100 cartons/min.