Direct-to-consumer (DTC) shipping models are creating new challenges and considerations for traditional secondary packaging strategies. According to a report by PMMI Business Intelligence, DTC requires increased durability for secondary packaging during distribution; causes challenges due to click-and-pick purchasing models; and creates concerns regarding security and tracking of products. It is also expanding secondary packaging to a reimagined role in the overall consumer experience.

And, 45% of manufacturers interviewed see enough current and future e-commerce business to warrant a separate line dedicated to producing, packaging, and shipping products exclusively for online channels, making this investment area one of future growth.

Packaging Durability

When manufacturers ship DTC from their production sites, secondary packaging must be highly durable as packages traveling through the DTC supply chain are handled an average of twenty times more than retail products. Customers routinely say that product integrity is a top concern, with a report from DHL citing 50% of online shoppers would not consider reordering from a vendor if they received a damaged product. This importance is not lost on manufacturers, as 50% of interview participants said they are looking to increase the durability of their secondary packaging.

Some are even taking packaging durability a step further by converting the primary package into a format suitable to serve as the secondary package during distribution. In this model, the primary and secondary packaging models are replaced with a single packaging option that is attractive enough to serve as the primary package, yet durable enough to survive the rigors of distribution. This model is seeing growing adoption, with 40% of participants exploring the concept of converting their primary package so that it can serve double duty as the secondary package during handling.

Click-and-Pick

Consumers now have an expectation that their orders will be rapidly and accurately filled when shopping online, and as a result many DTC models rely on bin picking, which is processed in real time as orders flow into the operation. Many of these picking operations have relied heavily on manual labor, due to the complexity of assembling larger orders.

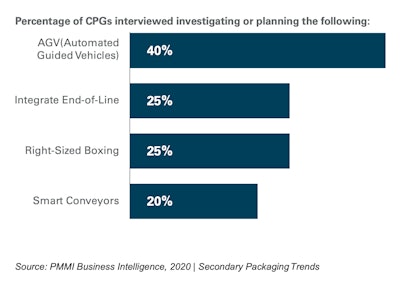

Companies engaged in e-commerce and DTC are looking for new automated solutions that are flexible and innovative, such as autonomous guided vehicles (AGVs) to roam the plant floor and deliver products/materials (40%), and integrated, smart conveying systems that allow for more accurate control of the flow of products in an operation (20%).