This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Norwalt, a specialist in custom-built automation and line integration machinery for complex manufacturing applications, announces its strategic partnership with ei3, a distributor in industrial Internet of Things (IIoT) solutions. Together, the companies have launched Norwalt Nexus, an AI-driven digital platform designed to transform conventional manufacturing equipment into intelligent, proactive systems.

The Nexus platform, now being integrated across Norwalt’s automation systems, addresses the growing talent crisis and increasing demand for smart, data-driven manufacturing. As manufacturers face over 500,000 unfilled positions in the U.S. and accelerating pressures to implement Industry 4.0—particularly in regulated industries where compliance and traceability are critical—Nexus empowers operations to achieve more with fewer resources, unlocking new levels of performance, uptime, and insight.

“With Nexus, we’re taking Norwalt’s precision-built machines and giving them a brain,” says Mike Seitel, Chairman of Norwalt Automation Group. “By combining our mechanical engineering expertise with ei3’s advanced IIoTtechnology, we’re enabling smarter decisions, predictive maintenance, and continuous improvement, without the need for specialized tech staff.”

Key Features of Nexus:

- Proactive Maintenance: Predict issues before they occur using AI and real-time wear tracking

- Custom Alerts & Dashboards: Stay informed with personalized alerts and performance reports

- Version Control: Automatically back up and track all system changes through Nexus

- Visual Intelligence: Smart video monitoring tied directly to system events

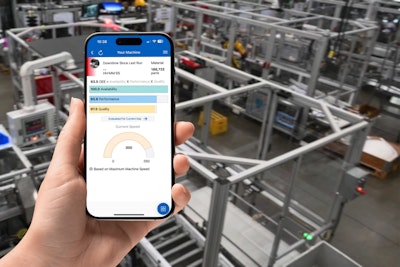

- Mobile Accessibility: Monitor diagnostics and performance remotely via the Nexus app

“Norwalt's integration of our IIoT platform brings the power of data intelligence to the heart of high-performance automation," says Spencer Cramer, CEO of ei3. "Together, we're helping manufacturers achieve actionable visibility with enterprise-grade security while reducing downtime and driving efficiency gains."

By providing an always-on digital operations expert that works around the clock, Nexus addresses gaps in talent, training, and system knowledge. It ensures that manufacturing intelligence stays embedded within operations, not lost with employee turnover. This partnership reinforces Norwalt’s commitment to delivering future-ready solutions that go beyond automation. With Nexus, customers gain not just a machine, but a continuous optimization engine that evolves with their business.