This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Compass Wire Cloth, a North American manufacturer of separation, sifting, and screening solutions, highlights its advanced Ultrasonic Screens. These screens are engineered to address the persistent challenges of material processing, such as blinding and pegging, while significantly boosting throughput and operational efficiency.

The Ultrasonic Screens incorporate a patented Frequency Variation Method, which allows for maximum ultrasonic excitation efficiency. This innovative technology intelligently searches for the optimal operating point, enabling smooth ultrasonic vibrations across various screen geometries without altering the structure of the application itself. As a result, users can expect enhanced performance tailored to their specific needs.

A standout feature of these screens is the ability to increase screening throughput while simultaneously reducing dynamic stress on the mesh. The design includes a converter located outside the screening area, ensuring no direct product contact and thereby enhancing hygiene and minimizing contamination risks. Additionally, the screens are ATEX certified, making them suitable for use in potentially explosive environments.

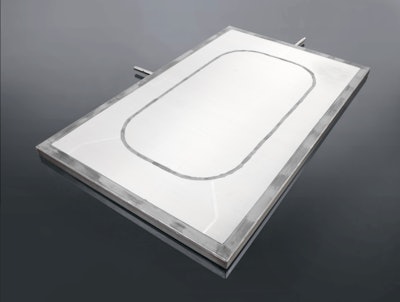

Compass Wire Cloth's Ultrasonic Screens are versatile and can be retrofitted to all types of screening machines, including tumbler and vibrating screens. Their robust construction from stainless steel ensures durability in harsh industrial conditions. The single-panel design facilitates quicker screen changes, resulting in reduced downtime and lower labor costs.

The integration of an advanced PLC interface allows for external remote control, enhancing user-friendliness and operational synergy. Furthermore, the customizable nature of these screens means that they can be tailored to meet specific operational requirements, providing a complete package from a single source.