This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

refleXions uses patent-pending technology in an in-line process to offer a cost effective alternative to metalized polyester, metalized transfer or hot foil stamping. Reflective design elements can now be efficiently and selectively applied in a single process. This is the first major innovation launched by the recently merged AGI-Shorewood.

"refleXions greatly expands our clients’ design options by bringing together manufacturing technology and creative for branding excellence and operations efficiencies," said Duncan Watson, Vice President of Creative Services at AGI-Shorewood. According to Watson, clients who have had a sneak peak of refleXions have declared it a "game-changing" industry breakthrough.

Superior Performance on High Speed Fill Lines

refleXions utilizes a traditional in-line printing application process that is more user-friendly than costly multi-step processes, such as hot foil stamping, metalized polyester or metalized transfer materials. By eliminating these multi-step material processes, the customer benefits from a more sustainable product with better machineability results at a lower price point.

By introducing a leaner production process and doing away with the need for additional steps, refleXions both increases speed to market and reduces the cost of reflective treatments.

Greater Design Flexibility through Selective Application of Reflectivity

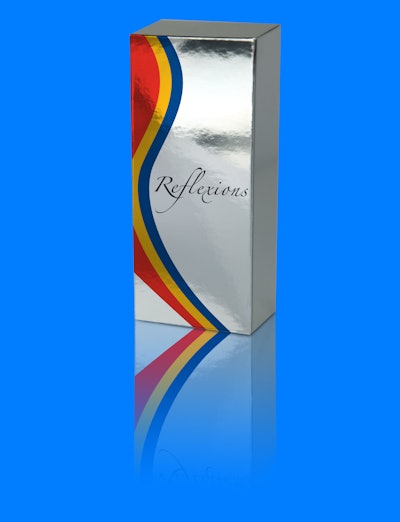

refleXions allows metallic details to be selectively applied to designs. This creates areas of high reflectivity (pure metallics such as silver, which can also be overprinted in selective areas with any transparent colors), as well as brighter white areas.

"For the first time, refleXions enables clients to place reflectivity only where they want it without layering over the metallic and diminishing the white, resulting in brighter white space," states Watson. "There has been a reluctance of some consumer packaged goods companies to use film products on their packaging due to costs and the limitations of high speed filling lines. refleXions gives us the ability to create fresh, dynamic designs that may not have been possible in the past."

Leading the Specialty Packaging Industry with a Commitment to Innovation

Continually evolving consumer tastes worldwide and growing markets in Asia and Latin America are driving packaging clients to seek new ways to enhance their packaging and attract customers with great shelf appeal. With an unparalleled network of design studios and manufacturing facilities across the globe, AGI-Shorewood is at the forefront of helping clients meet the needs of a vast array of markets and consumers.

"refleXions represents AGI-Shorewood’s commitment to develop pioneering technology to anticipate and respond to our clients’ need for cost effective, efficient production cycles with compelling design possibilities," Watson explains.

AGI-Shorewood - www.agishorewood.com