In June 2012, Asia’s largest paper company, Asia Pulp & Paper Group, published its sustainability strategy and goals for the next decade in the Sustainability Roadmap Vision 2020. Addressing environmental performance, biodiversity conservation, and the protection of community rights, the landmark roadmap represents AP&P’s attempt to develop its own certification standards for responsible forestry based on international best practices. Unique to its strategy is the roadmap’s transparency: Not only did AP&P solicit input from a multitude of NGOs—some of which, like Greenpeace, have been highly critical of its forestry practices in the past—but it also invited those NGOs to monitor its progress.

Among the main goals cited by the roadmap in relation to fiber sourcing are the following:

• 100% independent third-party verification for pulpwood legality

• Zero use of High Conservation Value Fiber (HCVF)

• Use of 100% plantation wood for its pulp production

• Use of 100% Sustainable Forest Management (SFM)-certified pulpwood

• Maintenance of a sustainable proportion of recovered fiber in addition to renewable virgin fiber

In February 2013, AP&P brought its commitment forward by three years, introducing its Forest Conservation Policy (FCP), developed with assistance from The Forest Trust (TFT). The FCP pledged a halt to all natural forest clearance across its entire supply chain, including HCVF and HCS (High Carbon Stock) fiber, in Indonesia, called for the protection of peat land, set forth a formal process of Free, Prior, and Informed Consent (FPIC) of indigenous people and local communities, and introduced measures to ensure sustainable fiber sourcing from its suppliers throughout the world.

With the announcement of the FCP, APP-China also launched a pilot online Monitoring Dashboard in mid-2013 that provides access to updated technical information, to enable stakeholders and third parties to actively review its progress toward implementing the policy. “This represents an unprecedented commitment,” says Henry Shen, Culture & Communications General Manager for Sinar Mas Group – APP China. “No one has ever done this before.”

In October 2014, Shen and his colleagues at APP welcomed journalists from four North American trade journals, Packaging World/Greener Package among them, to visit several of the company’s Chinese facilities to learn how these sustainability commitments are being administered on the ground.

Largest paper company in China

A subsidiary of Indonesian conglomerate Sinar Mas Group, APP comprises a group of pulp and paper manufacturing companies in Indonesia and China having a converting capacity of more than 18 million tons. APP-Indonesia and APP-China currently market their products in more than 120 countries, across six continents, including North America.

In a visit to APP-China’s headquarters in Shanghai, Shen provided an overview of the group’s footprint in China. Entering the country in 1992, APP-China now represents US$6 billion of the APP Group’s US$11.3 billion in sales, with a GDP several times that of China’s current 6.5% to 7% GDP growth. Shen says APP-China has achieved this growth by adding capacity to meet the demand fueled by e-commerce and the rise of the middle class in Asia. “The middle class in China wants the same conveniences that other countries have,” he explains.

APP-China currently operates two nurseries and seven paper mills and pulp plants, including Guangxi Jingui Pulp & Paper Co., Ltd., which operates one of the largest paper machines in the world, with a 1.2-million-ton rated capacity. Its plantations encompass approximately 1,158 sq mi in eight Chinese provinces under the APP China Forestry division. Products include graphic papers, packaging board, and tissue.

According to Shen, APP-China has been responsible for a number of sustainability firsts in China. The company was the first to conduct a carbon footprint assessment for its supply chain; in 1994, it pioneered the practice of plantation-pulp-paper integration, reducing its reliance on imported raw materials; has created a benchmark in the industry related to lower emissions from its mills; and several of its mills were the first to commit to the UN Global Compact’s CEO Water Mandate, an initiative designed to assist companies in the development, implementation, and disclosure of water sustainability policies and practices. By the end of 2012, APP had invested more than US$97 million in environmental protection in China.

“We want to set the standard for what it is to be a pulp and paper company,” says Shen.

From tissue sample to tree

Located in the South China Sea, China’s Hainan Island is home to APP China Forestry Management’s headquarters. It was here that journalists on the October media visit learned about APP-China’s planting and harvesting practices and toured one of its nursery facilities as well as several of its plantations with Dr. Wending Huang, Deputy CEO of APP China Forestry.

APP founded the forestry management department under the principle of “Compliance with laws, integrated planning, and scientific forest plantation,” actively developing the modern forest industry and promoting the green circular economy of plantation-pulp-paper integration.

According to an overview of the department on APP’s website, “on the premise of compliance with national laws and local policies, the company adheres to the philosophy of scientific management and eco-friendly forest plantation as well as the practice of intensive management to actively set up fast-growing forest bases. APP attaches great importance to environmental protection.”

In Hainan, APP’s plantations cover 173,000 acres, with 1,600 to 2,000 trees/acre, and are located on land rented from local farmers and owners. (Most of China’s land is state- or collective-owned.) Given the limited area available in China for farming, plantations are distributed in mosaic-like patterns, clustered between other land uses such as agricultural cropland and fruit orchards. According to Dr. Huang, this distribution pattern enhances the environment by providing diversified landscapes and vegetation, biodiversity, and buffer zones.

APP’s plantation fiber comes primarily from eucalyptus and acacia trees, which are highly renewable and sustainable due to the region’s tropical climate. Eucalyptus trees can be grown and harvested in just four to six years, while poplar—another variety grown by APP—takes from eight to 10 years to mature. APP also engages in coppicing, a forestry practice that takes advantage of the fact that these tree varieties can make new growth from the stump once the tree is cut down.

For example, as Dr. Huang explained, once a eucalyptus tree is harvested, shoots grow from the side of the stump. APP then selects the two most viable, and from there, two trees grow from a single stump. While a first-generation eucalyptus tree takes up to six years to reach full growth of 20 m tall, the coppiced trees take just four years to reach the same height. Currently, Dr. Huang says APP has been able to grow up to three generations of coppicing—its goal is four.

Coppicing is one method APP is using to get more from its 172,000 acres. “Because we can’t increase the land we commission, we are working on technologies to increase yield,” says Dr. Huang.

These technologies “take root” at APP China Forestry’s commercial nursery in Hainan—one of two in China—where tissue cultures from robust trees are used to grow clones. The 106-acre nursery includes a lab where select tissue culture material is placed into glass jars containing a growing medium and is stored on racks in an indoor greenhouse. “A large number of clones then start growing in the jar. These are then divided down into quantities of twenty-five, which begin establishing roots,” explains Dr. Huang. “Seventy percent of these will become trees.”

After 45 days, each seedling is transplanted into a tube wrapped with compostable material and filled with soil mixed with bark and coconut shavings, where it remains outdoors at the nursery until it grows to a height of 25 cm. At this point, it is ready to be planted in one of APP’s plantations in Hainan. APP says it plants from 5 million to 10 million seedlings/yr. According to Dr. Huang, the company is currently experimenting with 10 different spacing patterns to determine which ones provide the greatest harvest. “We have to be very intensive in every aspect of the process to have a good yield,” says Dr. Huang.

Green forestry management

At the plantation level, APP Forestry Management uses a number of practices that contribute to sustainable development. Among them are its green fertilizer programs, including intercropping of green manure, whereby APP has reduced the use of chemical fertilizer through inter-row planting of nitrogen-fixing crops, such as legumes, that improve soil conditions. In addition, APP collects biodegradable debris from harvesting sites to produce composite fertilizer that is then returned to the forest plantation sites to improve soil quality.

Enrichment of the plantation composition, structure, and diversity is also achieved through agro-forestry, in which local farmers grow crops such as rapeseed, cassava, pineapples, peanuts, medicinal herbs, and teas, among others, within the plantations. Local communities are also given the opportunity to use non-timber land for livestock grazing, poultry farming, and apiculture.

In order to operate its plantations in Hainan, APP-China must comply with all legal guidelines for the harvesting and transportation of wood, including harvest quota, harvest permit, harvest operation, and wood transportation, to ensure the integrity of the wood supply. Both internal and external programs have been established to monitor and audit the company’s compliance, including monitoring by third parties.

In 2011, Hainan Jinhua Forestry Co., Ltd. was among five APP-China companies that underwent a final audit and achieved forest certification from the China Forest Certification Council (CFCC).

High-tech papermaking

In Ningbo, a seaport city located 150 km south of Shanghai, journalists were treated to a tour of Ningbo Asia Pulp & Paper Co., Ltd. by Sales & Marketing Head Anton Hui. The 1.76-million-sq-m facility operates one papermaking machine, producing folding boxboard for packaging, art board for shopping bags, and duplex card stock for playing cards. Installed in 2005 by Metso, the facility’s papermaking machine has a capacity of 750,000 tons/yr.

Among the mill’s specialties is the ability to produce multilayered paperboard using both virgin and recycled material. The Ningbo facility utilizes recycled newspapers, office paper, and magazines as its raw material for recycled product. According to Hui, one ton of recycled material represents 70 trees. “We have made a significant investment to accommodate recycled materials here,” he says.

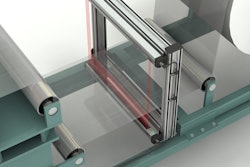

Covering a distance of 408.5 m (0.25 mile), the Metso BM7 machine has a width of 8.1 m, produces board from 300 to 500 microns, and operates at a speed of 900 m/min.

As part of APP-China’s commitment to protect the environment, the Ningbo Asia Pulp & Paper mill and machine are equipped with a number of green papermaking technologies. Among them, the company has designed and constructed two wastewater treatment systems with the capacity to treat between 4,000 to 4,500 tons/day. In addition, the facility boasts the lowest water consumption for each ton of paper produced in China—17 tons versus an average of 60 tons. Another technology, representing an investment of US$6.4 million, allows the facility to store and transport coal in an enclosed space. (See “AP&P Q&A: Asia Pulp & Paper speaks on sustainability” for more information on the company’s papermaking technology.)

In 2005, Ningbo Asia Pulp & Paper received ISO 14001 international certification for environmental management.

One year in

In February 2014, AP&P celebrated the one-year mark for implementation of its Forest Conservation Policy. And, according to all accounts, the company has demonstrated a sincere and concerted effort to meet its commitments since the FCP was announced. Said Scott Poynton, Executive Director of TFT at an event commemorating the anniversary, “One year in, and we have a moratorium of forest clearance in all its suppliers that has proven to be effective. HCV and HCS forest assessments are being completed, a number of social conflicts have been solved, and there is real transparency in reporting progress against its policy.

“We understand that complete trust isn’t built in a day and not even in a single year, but the company is listening to concerns and is ready to continue to implement and improve its FCP implementation. APP is 100 percent committed to zero deforestation.”