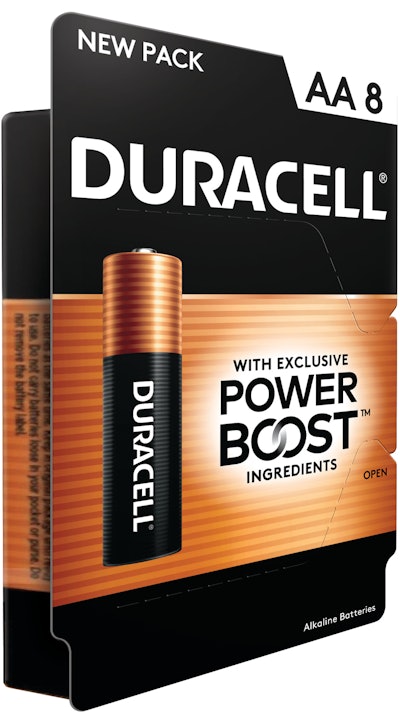

Duracell’s iconic copper-topped batteries are hitting Walmart shelves in new packaging. Individual packs of batteries are now packaged in curbside recyclable, all-cartonboard, paper-blisters that replace the legacy format of thermoformed plastic blisters affixed to cardstock backing.

“The packaging plays a key role in helping the shopper navigate the shelf. We reinforce the key decision-tree points (variant, package size) on both the front if looking straight on, and now the top of the packages if looking down. This helps the shoppers quickly and easily find what they are looking for. The packages will always be merchandised on shelving,” says Brandon Barr, GM, Retail Innovation, Duracell North America.

While the precise details were sparse, the company revealed that Algus, Proseal (JBT), and Koch Pac-Systeme GmbH packaging equipment features in the new automated primary packaging lines. Rohrer is the material supplier, and the packs are printed offset, two-sided, four-color with coatings. They are formed from flat blanks with pressure, then heat sealed.

Paper-based packaging is set to reduce Duracell’s plastic use by up to 100% from the traditional plastic packaging found on store shelves today, the company says. In Walmart alone, the overall packaging material will be reduced by approximately 855,000 pounds per year, while also eliminating more than 170 metric tons of carbon dioxide from landfills annually. The redesigned display and new packaging are major steps toward reducing the use of plastic and waste and, Duracell says, represents an important sustainability milestone in the battery industry.

Duracell’s new paper blister packs will be presented in a new, at-shelf retail experience that the company says will streamline the way consumers buy batteries. Each pack will be arranged/placed on the display—the company calls this the fixture—at retail. According to Duracell, the new shelves are designed with a roller mat and pusher system that allows inventory to always be front-faced and consistent for the shopper. The new category fixtures are designed to maximize speed of navigation for the shopper, while also reducing labor and complexity for retail employees and in-store merchandisers. The fixtures are set up in a vertical brand block, with the brands arranged from left to right as best, better, and good brands within the Duracell family.

New pack allows for retail shelf experience

Since we at Packaging World often wear packaging-centric blinders, we asked Duracell a foundational question: what is a retail shelf experience?

“The retail shelf experience is the process of the shopper finding, navigating, and selecting their product in stores. The new retail at-shelf experience is designed to address key shopper pain points with the combination of the new package, graphics, and fixture. These changes enhance category find-ability and increase the speed of navigating the category (23% faster now) to improve overall shopper satisfaction,” says Barr. “This [project] is a simplification of the category by re-designing the shelf to flow with the shopper decision tree in combination with key data such as variant, pack size, etc., now communicated on both the fixture and package. All with a focus on speed of navigation.”

And how does the package feature into this experience?

“At its core, the new package is what unlocks a lot of the new merchandising experience,” he adds. “[The new pack] is significantly more space efficient, allowing us to simplify the number of facings for shoppers but still maintain the appropriate inventory / holding power to maintain sales. They have flat bottoms which allow for them to be merchandised on the roller mat / pusher solutions keeping the packages front-faced at all times. And they have simple, clear reinforcement of key information that the consumer needs. For example, while looking down at the shelf, they can see the variant and pack count on the top of packages now too.”

The new approach, scheduled to roll out in retail stores across the nation starting at Walmart in early 2025, will enhance product visibility and set a new standard for retail solutions, the company says.

The new shopping experience will allow consumers to compare battery options between brands in a cleaner, more organized display that is positioned in an easy-to-find, permanent location in the store, providing a more efficient and pleasurable shopping experience. Additionally, all battery brands will be displayed side by side in new packaging, so consumers can easily compare ingredients, efficacy, and cost before purchase.

“We're leading the transformation of the battery shopping experience for consumers. By working with our retail partners like Walmart, we're helping to reduce point of purchase confusion, streamlining operations in-store, and making our packaging more sustainable than ever before, resulting in the removal of actual tons of plastic from the category,” says Roberto Mendez, president of North America, Duracell. “The product packaging and permanent display location in stores allow consumers to easily find and compare brands so they can choose the batteries they need with confidence.”

In addition to its consumer benefits, Duracell says it is bringing operational advantages to retailers. The displays will provide expanded shelf space to increase stockholding so less backroom space is needed. This will reduce the quantity of overall materials required for pallets, storage and transportation.

“We are excited to simplify the battery shopping experience for our customers,” says Tyler Lehr, SVP, general merchandising manager, Chilled Beverage & Convenience, Walmart. “Furthermore, the removal of plastic from the packaging is aligned with our mission as we continue on our path to becoming a regenerative company. Working closely with suppliers like Duracell on this project has been a step change in how we can drive excellence, deliver quality products to consumers, and enhance the shopping experience together.” PW