The EJ series offers many common components, while maintaining the possibility to configure different variants. The circuit board used with the EJ series is an application-specific signal distribution board that transmits signals and power to individual application-specific plug connectors in order to connect the controller to machine modules as required. Simple, prefabricated, “plug and work” cable harnesses replace often time-consuming manual wiring processes common in control cabinet construction. Unit costs are lowered, and the risk of incorrect wiring is reduced to a minimum with the coded components in the EJ system.

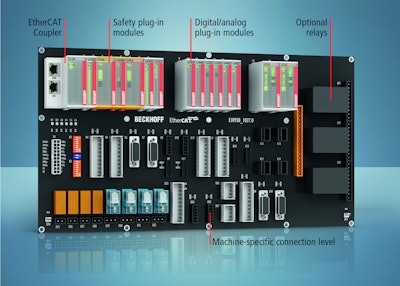

In large-scale machine production, expenditures for replicating controller configurations can be a significant cost factor. While traditional control cabinet wiring offers maximum flexibility and extendibility, this is not required when manufacturing hundreds of essentially identical machines. On the contrary, manual wiring of mass-produced machines is a common source of errors and causes high labor costs. The new EtherCAT plug-in modules introduce a highly efficient wiring solution into the series production of machines. In combination with industrial-grade cable harnesses, the signal distribution board – a circuit board specially designed by the user or by Beckhoff Automation – distributes signals and the power supply between EtherCAT plug-in modules and the machine.

Unit costs can be dramatically lowered through the automated production of circuit boards and cable harnesses – the higher the production volume, the greater the savings. The risk of incorrect wiring is reduced to a minimum, since the EJ series EtherCAT plug-in modules and the plug connectors on the cable harnesses offer convenient coding options.