This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

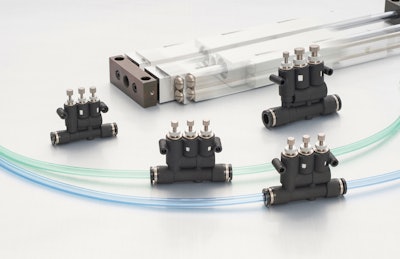

These flow controllers use a 2-stage speed control to regulate exhaust speed and to absorb shock in pneumatic cylinders.

Pisco flow controllers have 3 needles to adjust the initial speed of the cylinder (first stage), speed of the brake (second stage) and timing of the speed shift. The second stage speed of Pisco flow controllers provides a cushion and reduces the speed at the end of the stroke. This speed reduction also lessens shock by up to 1/9 while retaining the same cycle time. In a system that uses conventional shock absorbers and Pisco flow controllers, it is possible to actuate the initial cylinder stroke at twice the regular speed and then actuate the end of the stroke at the regular speed to reduce cycle time without increasing shock.

Cost benefits of this flow controller are achieved from a combined 2-in-1 design and long-lasting performance. These 2-stage speed controllers last three times longer than a system equipped with conventional shock absorbers and they require less maintenance. In a conventional system, shock absorbers require frequent replacement, resulting in significant costs over the life of the product.

Pisco’s flow controllers are available in 4mm, 6mm and 8mm metric sizes and 5/32, 1/4 and 5/16 inch sizes.