The AGR series provide accuracy to 20 arc seconds, with 8 arc seconds bi-directional repeatability, 30 rpm maximum speed, and 360° continuous or optional limited travels. Tilt error motion is 10 arc seconds, axial error motion is 5 µm, radial error motion is 10 µm and maximum axial load is to 425 kg.

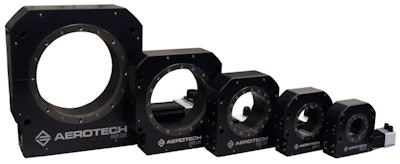

Larger clear apertures are available from 50 to 200 mm diameter. This feature allows the AGR series to address applications requiring a through-hole or accommodations to mount an optic, including articulation of beam polarizing lenses, through-holes for cabling and/or air lines, or vision/camera/inspection applications.

The AGR stage base is fabricated from an aluminum alloy that offers significant weight savings in multi-axis arrangements and other weight critical applications, while providing high structural stiffness and long-term stability. Each stage is designed with two high-precision angular contact bearings with optimal spacing to provide quality error motions coupled with high load capacities in a compact package.

Options include brush, brushless, and stepper motor selections as well as a direct encoder mounted to the stage shaft for repeatability and elimination of hysteresis and backlash. A full range of matching drives and controls are available for a complete single-source solution. Vacuum-compatible versions for use in pressures as low as 10-6 torr are available.