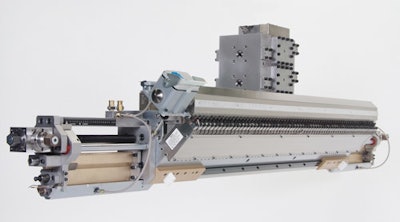

Extrusion Dies Industries LLC's (EDI) new generation of its EPC™ extrusion coating die, introduced at PACK EXPO, increases productivity by simplifying changes in product width and eliminating much of the deckle disassembly involved in cleaning and maintenance, the company says.

As in the past, the EPC die incorporates a deckle system that can be adjusted to minimize the formation of edge bead, which wastes polymer and substrate as it is trimmed from the web.

"What is innovative in the new-generation EPC die is an extensive enhancement of the deckle system that increases the ease and repeatability of width adjustments, simplifies clean-out of carbonized polymer buildup in the die, and makes possible rapid removal of the entire deckle assembly for a ‘split and clean,' or complete opening of the die for maintenance," explains Gary Oliver, vice president of technology and engineering.

Deckles are mounted at either end of a die and used for varying the coating width. The die includes an external deckle to prevent leakage and an internal deckle system with independently adjustable components that seal off portions of the internal flow channel and can be positioned to minimize edge bead.

The new-generation EPC die includes innovations that reduce time in four ways:

• Rapid and accurate changes in width.

• An easily inserted scraper to remove buildup.

• Ready access for replacing seals and adjusting die gap.

• Fast removal of deckle systems for "split and clean."

As in the past, the EPC die incorporates a deckle system that can be adjusted to minimize the formation of edge bead, which wastes polymer and substrate as it is trimmed from the web.

"What is innovative in the new-generation EPC die is an extensive enhancement of the deckle system that increases the ease and repeatability of width adjustments, simplifies clean-out of carbonized polymer buildup in the die, and makes possible rapid removal of the entire deckle assembly for a ‘split and clean,' or complete opening of the die for maintenance," explains Gary Oliver, vice president of technology and engineering.

Deckles are mounted at either end of a die and used for varying the coating width. The die includes an external deckle to prevent leakage and an internal deckle system with independently adjustable components that seal off portions of the internal flow channel and can be positioned to minimize edge bead.

The new-generation EPC die includes innovations that reduce time in four ways:

• Rapid and accurate changes in width.

• An easily inserted scraper to remove buildup.

• Ready access for replacing seals and adjusting die gap.

• Fast removal of deckle systems for "split and clean."