What comes first, the specification of a standard or its commercial implementation? It depends who’s doing the developing. With consumer technologies like USB and Bluetooth, the manufacturers tend to get together and hammer out the standards so they can bring products to market.

Example: new regulations drive safety

Sometimes the same is true in the packaging industry -- most recently when Ethernet Powerlink SG offered the OpenSAFETY open source safety protocol to all industrial fieldbus groups during Hannover Fair in April.

At other times, new standards are legislated by regulatory changes, increasingly from the EU. For example, bans on genetically modified crops and the CE rating have become de facto world standards because commodities markets don’t distinguish between end customers and no one wants to produce different versions of products if they can help it.

And in terms of safety, there’s a liability issue – if you make a product to higher European safety standards to sell in that market, a jury may decide you short changed your North American customer.

Where does PackML fit in the adoption cycle?

What this has to do with PackML is simple. It’s one of those standards driven by visionary end users, not law. Most of the original proponents aren’t even in automation roles in CPG any more -- people like Unilever’s Andrew McDonald, Hershey’s Keith Campbell, and P&G’s Dave Chappell (who is actively involved as a consultant).

It was developed through substantial technical resources provided by the controls suppliers who heeded the call because it was in their best interests to change the status quo. Properly implemented, standards foment a healthy sense of competition because they break down proprietary barriers to trade. Think VoIP. That’s compared to the status quo that says, ‘yes, there should be a standard and it should be mine.’

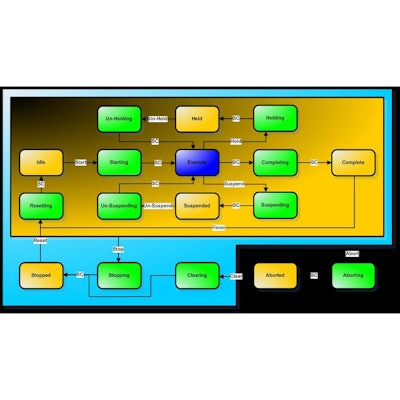

PackML, like OPC, enables uniform data acquisition for important new trends like safety, Manufacturing Execution Systems, packaging line integration and Overall Equipment Effectiveness.

If PackML is such a game changer, what’s holding it up?

There’s a third party, that’s what. And ‘if you build it, they will come’ doesn’t work for them because unless it’s in the specification for your packaging machinery, machine builders aren’t likely to embrace a new standard. They’ve been burned before by spending money on new industry requirements that turned out to be dead ends. Think reverse auctions at the turn of the century. Machine builders say ‘if you’re buying it, we will build it.’

What’s happened is that, like the early days of bar codes, at the plant level a maintenance manager concerned about fixing what doesn’t appear broken can override an important new corporate spec. Adoption stalls. And that is a pity, a real Catch-22. What is the incentive at the plant level to make any change that could be perceived as disruptive, or require taking techs, engineers or operator to go offline for training? Think bundled cable providers – we put up with them because we’re too busy to investigate alternatives.

It’s frustrating, but seems also to be part of any revolution. People put up with the ‘devil you know’ for a long time unless some rabble rousers come along and rally people to demand change.

Enter the first movers on the OEM side

In the case of PackML, some highly regarded packaging machine builders did comply with the standard – companies like ADCO, Pearson and Pro Mach. They listened and believed, but the specification languished between corporate visionaries and plant level specifiers. Trade publications and industry groups have promoted the standard for years now – including a recent Packaging World cover story and speakers and workshop at this year’s Packaging Automation Forum -- but the power of publicity has yet to turn the tide.

As recently as June of this year, pundits at conferences admonished packaging machine builders to push PackML to their customers, the packagers. The irony is that, while standardizing on states, modes and tag naming conventions will ultimately benefit machine builders, the immediate and greatest benefit is to packagers.

Bottom line: machine builders don’t make a lot of money on PackML, but packagers do, and there is a disconnect between corporate and plant at packagers that is preventing adoption from happening as it should already have taken place.

What is the answer? Somewhere between corporate engineering and plant engineering lie the business units’ P&L owners.

The first movers’ next move

That’s where a group of early adopters of PackML is heading B&R Industrial Automation’s John Kowal is helping organize ‘PackML World Tour 2010’ to connect machine builders with CPG proponents of PackML. The purpose of the meetings is to determine who else at these companies needs to be engaged to understand the business advantages of PackML’s enabling technology.

With one foot in the Packaging Machinery Manufacturers’ Institute leadership and another in PackML’s parent organization -- as a board member of the Organization for Machine Automation & Control (OMAC) -- John is in the right position to make something happen.

If you’re a machine builder who has adopted PackML and would like to be part of the upcoming Tour, contact John at [email protected].