Thus begins an insightful article by C. Kenna Amos in the July issue of Automation World that serves as a valuable update on the ongoing packaging machinery trend towards integrating logic, motion, and communications in one controller. Highlights:

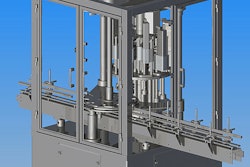

* Sentry Equipment & Erectors introduced a new line of machines this summer that will shrink wrap, tray pack, and case pack. Gen3 technology allows end-users the flexibility of multiple formats on the same chassis and quick changeovers from one format to another. The traditional mechanical drive train is eliminated by placing a servo axis on each motion axis to reduce part count and minimize the footprint of the machine. The use of Elau’s PacDrive controller lets an end-user communicate with factory-level data acquisition systems and management control systems in a variety of formats, including Ethernet, TCP/IP, OPC, and Web-based services.

* Cloud Packaging Solutions is using Siemens Simotion controller (which incorporates motion control with integrated object functionality as well as temperature, pressure, and other controls) to build a packaging machine for a European food marketer. Cloud is implementing safety controls on the machine through the Simotion PLC function. New this year, this functionality eliminates discrete safety relays, greatly simplifies wiring, and integrates fault diagnostics into the safety system. That data is displayed on the HMI.