Polypropylene is one of the most widely used plastics in consumer packaging, yet in the U.S., more than 90% of it still ends up in landfills or incinerators. A major new effort aims to change that. Led by Nextek Ltd., the science-based consultancy founded by Professor Edward Kosior, the Nextloopp initiative is uniting stakeholders across the packaging supply chain to enable the closed-loop recycling of food-grade PP.

Nextloopp originally launched in the U.K. in 2020 and is now expanding its impact with the official launch of Nextloopp Americas. The inaugural, virtual meeting took place today, gathering a cross-section of industry stakeholders from across North and South America. The meeting formally introduced a number of Nextloopp's foundation partners—Tomra, Gneuss, NGR, Hydrodyn, Bekaert, Eunomia, Heng Hiap, and Advanced Plastic Systems—and outlined the initiative’s phased strategy for scaling food-grade recycled polypropylene (rPP) through collaborative trials, AI-enabled sorting, and market-building efforts.

Nextloopp

Nextloopp

“We believe polypropylene is on the same journey that PET was on many years ago,” said Kosior during the launch. “We know the pathway, we've got the steps, and we have the technologies to do that in the Americas.”

The meeting highlighted the group’s upcoming AI-sorting demonstration, planned for September 17 at Tomra’s R&D center in Germany, and emphasized support for existing recyclers with Letters of Non-Objection (LNOs) from the FDA. “We want to give recyclers the confidence and technologies to be able to go to market,” Kosior added. Nextloop Americas Project Manager Marcio Amazonas echoed the collaborative spirit of the initiative, noting that Nextloop is creating “a safe space for innovation, regulation compliance, and market development across the full polypropylene value chain.”

Why recycled PP matters

Polypropylene’s widespread use in packaging makes it a critical target for improving recycling outcomes, yet it has long lagged behind materials like PET in terms of collection and reuse. According to Kosior, “Polypropylene is as big a packaging material as PET, so it should be recycled in the same volume.” However, the reality has been starkly different—especially in the U.S., where only about 8% of PP packaging is currently recycled.

Kosior attributes this gap to the fact that PP is often used in formats like pots, tubs, and trays, which were historically overlooked by recycling programs that prioritized bottles and cans. And the implications go beyond just environmental concerns. As Kosior points out, the low recycling rate of PP also creates an economic disadvantage for recyclers. “They have to compete with post-industrial recycled materials... so they get very small values,” he says. In contrast, producing food-grade recycled PP opens the door to higher-margin markets. “They’ll get a premium over virgin plastics because they’ll be able to sell into a market that is under high demand.”

| Read this related article from the Plastics Recycling Conference, “The Next Step in PP Recycling: CPG Action” |

Recycling PP back into food-grade applications also has strategic value for the packaging industry, allowing true circularity. “For true circularity, we really need to take food packaging back to food packaging,” Kosior emphasizes. This not only helps recyclers capture more value but also enables brand owners to meet their recycled content goals—goals that are becoming increasingly urgent in the face of growing regulatory and consumer pressures.

Kosior notes that the current system isn’t just losing material; it’s missing an opportunity. With over a million tons of PP packaging produced annually in the U.S. alone, even modest improvements in recycling rates could dramatically increase the availability of high-quality recycled content.

Building the Nextloopp model

At the heart of Nextloopp’s success is a collaborative model that leverages technical innovation from across the packaging supply chain. While sorting and decontamination are core to the process, the project’s growth has been fueled by a diverse range of partners that have each addressed specific challenges to enable the production of food-grade recycled PP.

One of the most significant technological leaps within the Nextloopp initiative has been the integration of artificial intelligence into the sorting process. Traditionally, identifying food-grade versus non-food-grade polypropylene at high speeds posed a major barrier. Initially, the team used fluorescent markers on packaging labels to distinguish food-contact items, but this required widespread adoption and added cost. In partnership with Tomra, a foundational member, Nextloopp pivoted to AI-driven sorting that recognizes packaging types without the need for added markers.

“We started on the journey of sorting packaging using AI ... and now we can do this at five tons per hour,” explains Kosior. The system achieves up to 97% purity in food-grade material selection, enabling commercial-scale recovery with unprecedented accuracy and efficiency. This advancement has dramatically improved the viability of producing food-grade recycled PP from post-consumer packaging.

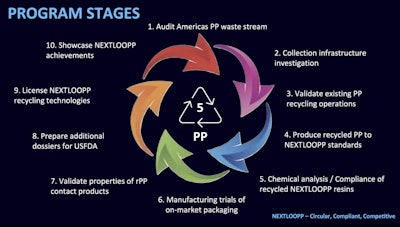

Nextloop circular recycling process: 10 stages of polypropylene waste management and reprocessingNextloopp

Nextloop circular recycling process: 10 stages of polypropylene waste management and reprocessingNextloopp

Several technology partners have brought solutions that go beyond the mechanics of recycling, addressing subtleties in design and material behavior that can make or break circular systems. For instance, one member company developed a label adhesive that fully detaches in hot water without leaving residue, preventing adhesive contamination during the wash stage and enabling a cleaner, purer recycled resin.

Another breakthrough came from a partner focused on dairy packaging, where aluminum lids are common. “That residual aluminum ... typically contaminates the recycling,” explains Kosior. To overcome this, the company created a polypropylene-based peelable lid, offering a mono-material alternative that is fully compatible with PP recycling streams.

Even subtle innovations, like the development of removable in-mold labels or resins that respond predictably during sorting, have contributed to Nextloopp’s broader goal of creating a packaging system that is technically and economically optimized for reuse. These contributions feed directly into what Kosior describes as “guidelines for good design for the circular economy”—standards that not only prioritize recyclability, but also ensure that recycled PP can return to high-value food-contact applications without compromising safety or performance.

The collaborative nature of these developments is what sets Nextloopp apart. As Kosior puts it, “We always knew that there would be things that we wouldn’t have discovered but other innovators have developed, and we can incorporate them into... the ideal process.”

Nextloopp comes to the Americas

The U.S. market presents a different set of challenges. Unlike Europe, where PP recycling infrastructure has matured, the U.S. is “about 20 years behind,” says Kosior. “Right now, 92% of PP packaging in the U.S. is not recycled. But the demand for food-grade recycled PP material is huge—over 250,000 tons annually.”

That disconnect—high demand, low supply—is what makes Nextloopp’s expansion to the Americas both urgent and promising.

Nextloopp Americas is structured to mirror the success of its European counterpart, with localized adaptations. It will work alongside groups like The Recycling Partnership and Closed Loop Partners, both of which are providing grants for MRF upgrades to boost PP collection and recovery. Meanwhile, Nextloopp will support recyclers with the technology and training needed to produce food-grade resin, including assistance with FDA Letters of Non-Objection (LNOs).

Kosior emphasizes that many recyclers already hold LNOs but lack the in-house technical capabilities to meet the stringent requirements for food-grade applications. “We can help them get there,” he says. “From sorting to washing to quality assurance, we provide the scientific and engineering support needed to scale.”

A supply chain solution, not a silver bullet

While technology is at the heart of Nextloopp’s work, the project’s true strength lies in its cross-sector collaboration. “This isn’t a chicken-and-egg scenario; it’s a supply chain challenge,” says Kosior. “Everyone from brand owners to recyclers to MRF operators needs to be at the table.”

| Read this related article, “Souvenir Stadium Cups Use 50% rPP from Purification” |

Nextloopp acts as a facilitator, allowing participants to share technical insights and connect commercially. Although the project itself doesn’t engage in material transactions, it enables matchmaking between stakeholders to help build the ecosystem needed to scale food-grade PP recycling.

Looking ahead, Kosior believes PP recycling rates in the U.S. could catch up to PET and HDPE rates at roughly 30% within a matter of a few years. “If we can demonstrate the economic case and create stable demand, recyclers will invest, MRFs will respond, and brand owners will meet their circularity goals,” he says.

The road to market

Kosior is optimistic about the speed of progress in the U.S., especially with a faster regulatory process via the FDA compared to Europe’s EFSA. “We expect approval of our technology from the FDA very soon,” he notes, adding that some Nextloopp members in the U.S. could be producing commercial food-grade recycled PP within the year.

The launch of Nextloopp Americas marks the beginning of that next chapter. “We’ve sharpened our pencils for eight months to prepare for this,” Kosior says. “This is about transforming a waste stream into a circular resource. And we’re ready.” PW