This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

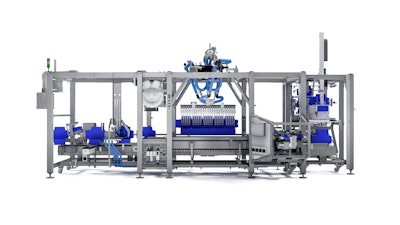

The All In One packer by CT Pack is a modular, integrated solution designed to streamline and optimize the entire end-of-line secondary packaging process. This compact machine combines carton forming, product loading, and carton closing into a single, efficient unit.

With a capacity of up to 600 products per minute, the All In One handles high-volume production with precision and gentle handling, thanks to its 2- or 3-axis robot equipped with flexible vacuum heads. It supports both single and dual infeed configurations, easily adapting to various production needs. Carton closing can be customized with different systems such as hood or lid applicators, ensuring secure and reliable packaging.

CT Pack

CT Pack

The frame, made of painted steel with FDA-compliant product-contact parts, guarantees a hygienic environment that meets food safety standards. Ideal for packaging multipacks, display boxes, and trays, the All In One offers significant space savings due to its compact design, reduces labor costs through automation, and boosts productivity.

CT Pack

CT Pack

Its intuitive touchscreen panel makes operation and maintenance straightforward and user-friendly. In summary, the CT Pack All In One packer is a cutting-edge, versatile solution for secondary packaging, designed to meet the efficiency, flexibility, and hygiene demands of modern production lines.