The Series 1500 wraparound and Series 1600 front-and-back labelers from Labeling Systems Inc. (www.labelingsystems.com) are equipped with a new FX3U PLC from Mitsubishi (www.mitsubishi-automation.com) that communicates freely with servos, variable-frequency drives, PLCs, and HMI over a single communications protocol. Better synchronization of all axes of motion is among the chief benefits gained. Less time spent programming is another, as LSI’s Andrew Dondero explains.

“This new PLC has a lot of built-in commands. In the past, we had to write our own command routines, including multiple rungs of ladder code. This is a much more modular approach, which we as machine builders appreciate.

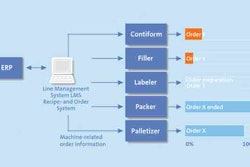

“For the customer who buys and installs such a machine, the advantage is that they can control the entire machine from a single touchscreen interface. In the past, if there were multiple labeling heads, there were multiple operator interfaces, start buttons, potentiometers, and so on. Now at a single interface the operator can change parameters not only on multiple labeling heads but also on the master conveyor speed, the wrap belt, the top hold down, and the infeed timing screw. All these devices communicate through the FX3U, the master PLC.”