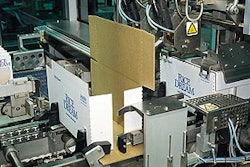

While U.S. Sugar added vertical form/fill/seal machinery to pack its private-label powdered and brown sugars, it decided not to invest in zipper applicating equipment. Instead, it buys rollstock with a zipper applied from a converter. “We considered buying a zipper applicating machine, or even a zipper-attachment device,” recalls Bill McDaniel, president and CEO of U.S. Sugar. “But our business is making sugar and putting it in bags. It’s tricky to package, and it’s a process we’re always trying to improve upon. Adding a complication like putting on zippers is not our business.” There was also a cost consideration. “We chose to let a converter invest in the equipment and deal with applying the zippers to the material while we focused on what we do best,” McDaniel notes. Reliable Poly Packaging bought its first Hudson-Sharp machine in January ’99 and now has its fourth and fifth machines on order. While converter Reliable would not divulge film suppliers, it did say the film’s polyethylene blends, which include linear low-density PE, help to deliver good sealing and anti-static properties for the bags of sugar. For U.S. Sugar, Reliable prints the materials flexographically in up to six colors. It then perforates an area along the film that later allows consumers to open the pack easily. Immediately after the perforation, the machine applies the zipper in registration. Unlike many zippers, the Inno-Lok version is applied in a transverse direction. When the filled, sealed package is laid flat with its front panel facing upward, the zipper is centered horizontally across the pack, about an inch from the top sealed edge. The zipper is unusual in that it’s applied only to the inside of the bag’s front panel as part of a strip of film that does not extend completely across the panel. Its male and female profiles are interlocked. Graphics printed on the outside of the strip include both the Inno-Lok and Zip-Pak trade names. Printed between them is a “Pull to Open, E-Z Tab” oval. When the consumer pulls on the tab, the perforation tears and the zipper opens, allowing access to the product. The zipper also allows for easy reclosing of the bag. By buying the Hudson-Sharp machines, Reliable Poly Packaging has made a serious commitment to zippers. “The ability to make pre-zippered rollstock is a new technology,” explains Marc Goldenberg, vice president of sales for the converter. “Until recently, anyone who wanted a reclosable package had to invest in the equipment, learn how to run it, and it would take a long time to get the pack to market,” he says. “Now they don’t need to make that investment, and they can start producing reclosable packs in four weeks on existing vertical form/fill/seal equipment. U.S. Sugar was the first in its industry to use it.” As U.S. Sugar builds its customer base, it increases its order volumes from Reliable. The converter anticipates that happening with other customers as well. Goldenberg says, “We justify the machinery by adding new customers, and we’re getting a lot of new customers because of this new product.”

U.S. Sugar zips into reclosable bags (sidebar)

Zipper application is outsourced

Jul 31, 2001

Companies in this article

Machinery Basics

List: Digitalization Companies From PACK EXPO

Looking for CPG-focused digital transformation solutions? Download our editor-curated list from PACK EXPO featuring top companies offering warehouse management, ERP, digital twin, and MES software with supply chain visibility and analytics capabilities—all tailored specifically for CPG operations.

Download Now

Conveyor setup secrets from top CPG manufacturers

7 proven steps to eliminate downtime and boost packaging line efficiency. Free expert playbook reveals maintenance, sequencing, and handling strategies.

Read More