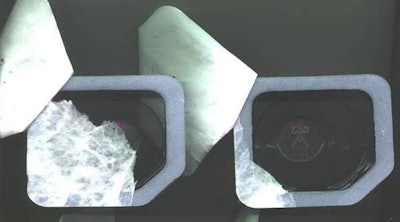

The diagram below demonstrates various lid placements on a tray and the predicted result after peeling. The first cause of fiber tear is improper lid placement and/or improper lid size. Lids should overhang the seal area of the tray by a minimum of 0.5mm. In an experiment conducted by DuPont, lid placement was a strong predictor of whether or not the lid would experience fiber tear during opening. The physics of peeling open a lid from a tray requires an adhesive break of the bond between the heat seal coating and the tray. A proper adhesive break leaves the heat seal coating on the tray (white witness mark) and allows the lid to peel cleanly away from the tray. An oversized lid allows for clean initiation of the peel. Avoid these factors and make great seals that peel open cleanly, as shown in the photo below.

Provided by DuPont

• Proper lid placement with minimum of .5mm lid overhang all the way around the tray

• 32 out of 32 samples with consistent seal area and no delamination during opening

• No overhang, lid length and width dimensions equal to tray seal area dimensions

• 26/32 samples experienced fiber tear ranging from minimal to extreme

Provided by DuPont

• Proper lid placement with minimum of .5mm lid overhang all the way around the tray

• 32 out of 32 samples with consistent seal area and no delamination during opening

• No overhang, lid length and width dimensions equal to tray seal area dimensions

• 26/32 samples experienced fiber tear ranging from minimal to extreme

Companies in this press-release