This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

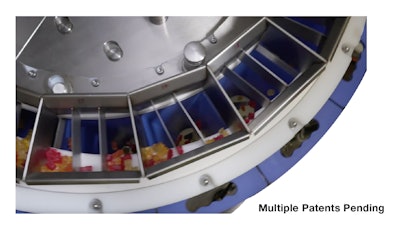

Capable of filling up to 180 bottles of various sizes per min, the Spee-Dee Packaging Machinery filling system deposits nutraceutical gummies from a multi-head weigher into a slide ring pocket with dividers which separate them. Next, the gummies are streamed into funnels by a wedge-shaped slide plate that ensures they fall in one by one. Smaller product clumps are separated by a funnel baffle to prevent bridging before the gummies are deposited into a container. The sanitary gummy system includes a rotary filler and integrates with a variety of multi-head weighers.