Spee-Dee Packaging Machinery, Inc.

Sturtevant, WI 53177

Designed for specific applications with simplicity in mind, Spee-Dee systems achieve accurate, reliable filling and weighing, and are backed by a commitment to service and quality.

Filling solutions and checkweighers for the food, pharma and nutraceutical industries

1 year parts and labor

Telephone support available 24 hours/7 days a week. In-house and field technical support.

In-house and field training; start-up, operations and maintenance. PMMI Certified Trainer.

In-house testing lab that can simulate full production runs; customer-site testing

Fill With Confidence

Since 1981, Spee-Dee has earned a reputation for building reliable, accurate and durable dry filling systems. Customers trust Spee-Dee to improve efficiency, productivity and profitability. Our test lab is second-to-none and offers the ability to simulate your full production line at our facility.

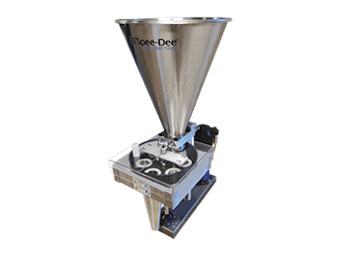

Auger Fillers

Increased accuracy, less giveaway and an improved bottom line is what you get with Spee-Dee augers. Produced with rigid engineering and manufacturing standards, our augers are ideal for dry fill applications such as ground coffee, powdered drink mixes, baking mixes, sugar, spices, soup bases, nutraceuticals and more. Our high speed rotary auger powder filler utilizes servo technology to eliminate time-consuming manual adjustments.

Volumetric Cup Fillers

Spee-Dee cup fillers have earned a reputation as the most reliable, accurate and durable available. Quick change cups can be easily inserted in minutes. Telescoping cups offer the ability to fine tune the fill weight for fill and weight accuracy. Servo drive cup fillers accurately fill at up to 140 per minute and are designed to serve a variety of packaging applications from a simple hand fill to interfacing with automatic equipment.

Rotary Fillers

Spee-Dee high-speed rotary fillers provide increased efficiency. Change times are reduced via an innovative funnel design, elimination of lengthy mechanical setups and closed coupled servo controls. An open design allows easy access to the entire system. Rotary fillers are perfect for powdered products in rigid containers at speeds up to 400 per minute.

Checkweighers

Improved accuracy, better communication and easy calibration. Use it as a stand-alone unit or integrates with any of our filling systems or your existing packaging line. Electro Magnetic Force Restoration (EMFR) technology guarantees precise and reliable weight measurement. It comes with a small footprint, non-proprietary PLC controls, tool-less belt changes and USB port for easy data collection. Sanitary, heavy-duty and inclined models are also available.

Danny Harmann

Robert Trabbold

Gary Lowden