This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

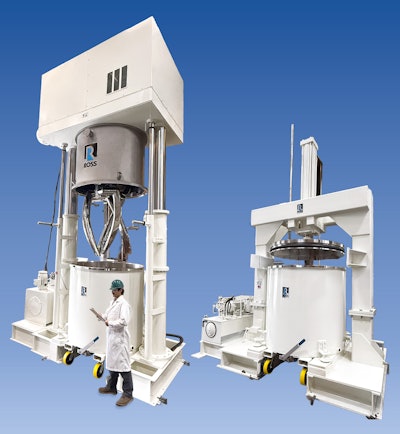

ROSS recently completed the largest Double Planetary Mixer in its US history, a Model DPM-750 capable of mixing up to an impressive 750 gallons per batch and engineered with safety features for a Class I, Division 1, Group D hazardous environment. This heavy-duty mixer delivers the robust agitation required for ultra-high viscosity materials while adhering to demanding safety standards.

A 150 HP inverter-duty motor powers a pair of High Viscosity (HV) stirrers that operate in a planetary motion ideal for turning over extremely thick, sticky, stiff or dense materials. Vacuum mixing to 29.5” Hg produces a void-free finished product and improves dispersion quality. The vacuum hood is customized to include various ports for ingredient charging, exhaust, and observation.

The mixer’s stainless-steel type 304 product contact parts are polished to an 80-grit finish, and interchangeable mix cans support flexible batch processing. The dual-post hydraulic lift features a 10 HP explosion-proof motor, dual hydraulic pumps, and integrated locks with proximity switches for precise, secure positioning. Safety interlocks disable operation unless the stirrers and mix can are properly positioned.

The accompanying ram-type discharge system is designed for fast, efficient product transfer and easy cleaning. A pressure-compensating hydraulic system maintains 60 PSI under the platen. In minutes, a 750-gal batch is pushed out of the 4” flush tank ball valve at the bottom of the mix can, while the platen O-ring scrapes sidewall surfaces on its way down, maximizing yield.