This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

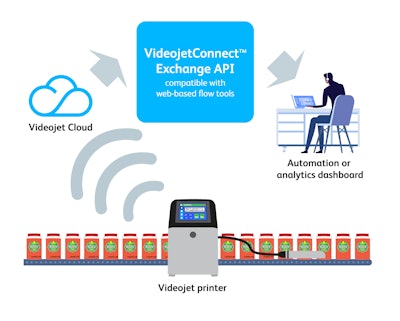

Videojet Technologies, a global supplier of coding and marking systems, has expanded its VideojetConnect Digital Services portfolio with the introduction of VideojetConnect Exchange, a programming interface that enables easy access to the data that is resident in most new and installed Videojet printers and lasers.

Through a cloud-based connection, the VideojetConnect suite of unique data capture and analytic tools is designed to help maximize the uptime of coding devices, track the performance of the packaging operation, and automate inline inspection processes.

With the introduction of VideojetConnect Exchange, manufacturers using standard programming methods can incorporate the data captured by VideojetConnect applications into their automation and analytic systems. “We appreciate that for many manufacturers, having a unique dashboard for each equipment vendor can be sub-optimal, especially when they may have already invested in a plant-wide IoT platform,” said Bob Neagle, Videojet commercial director of digital products and services. “VideojetConnect Exchange offers the best of both worlds, as individual coding device data can be processed and organized in the Videojet cloud and then easily integrated into other systems and dashboards for operations associates to use as part of their daily routines.”

Using a REST-API, IT and OT teams can create straightforward code to access the data they require. Web browser-based flow editors, such as Node RED, can be used to create the underlying calls and route the returned data. VideojetConnect Exchange is organized so that a common set of device status information can be accessed in a single call to reduce overhead. Its developer webpage provides working examples and the ability to browse and discover data sets and returned code examples that can be used for troubleshooting.

Views of the coding device information can be customized and set to reside in any convenient third-party IoT-supporting SaaS environment. Based on the typical role of the coding device in the production process, the possibilities for leveraging the data go beyond maintenance. Neagle added, “Coding device status and counts can often be the best representation of real-time production, while comparing related primary package and case coding device data can enable the calculation of quality yields or highlight bottlenecks in a production.”

VideojetConnect Exchange can be obtained as an addition to the base VideojetConnect Remote Service offering via a yearly subscription of an API key.