This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

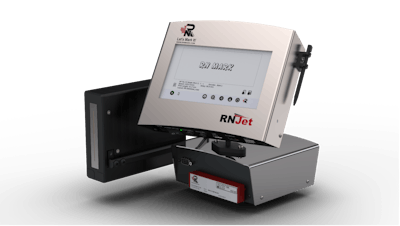

Pallet marking is essential in modern logistics. It ensures traceability, brand recognition, and regulatory compliance across distribution chains. The RNJet 72 is a high-resolution industrial inkjet printer built to meet these needs with unmatched efficiency. Developed in Canada, this innovative solution is not only budget-friendly and robust, but it also eliminates the need for high-maintenance printing systems.

This article explores why the RNJet 72 is a standout for pallet marking—offering affordable operation, zero-maintenance features, and industrial-grade reliability.

Made in Canada: Quality You Can Count On

Designed and manufactured in Ontario, the RNJet 72 reflects Canadian engineering excellence. Unlike outsourced devices, this printer benefits from close-knit design, manufacturing, and support teams. Local production ensures higher quality control, shorter lead times, and fast, responsive service.

Choosing a Canadian-made product also ensures compliance with North American standards, and companies benefit from easy access to parts and tech support. For logistics managers and manufacturers in North America, this is an invaluable advantage.

A Cost-Conscious Investment

Many operations spend thousands on labels, replacement printheads, or frequent maintenance for traditional printers. The RNJet 72 was built with affordability in mind:

• No labels required: Print directly onto pallets and wooden surfaces. This eliminates the cost and handling of preprinted labels.

• Smart ink use: Built-in ink consumption tracking and low-ink alarms ensure that you're never wasting resources or suffering from unexpected shutdowns.

• Reduced labor: Automated printing functions reduce the need for constant human supervision.

The total cost of ownership for the RNJet 72 is significantly lower than most comparable systems, especially over long production runs.

Truly Maintenance-Free

One of the biggest advantages of the RNJet 72 is that it’s virtually maintenance-free. It’s engineered for long runs, tough environments, and minimal oversight.

• No daily cleaning: The ink system resists clogging and requires no routine clean-up.

• Long-lasting cartridges: Ink refills are straightforward and clean. Plus, the system monitors usage, ensuring timely alerts.

• Durability built-in: The design is rugged, built to endure industrial environments without fail.

This means no surprise downtime or mid-shift disruptions—just smooth, consistent operation.

High-Performance Specifications

The RNJet 72 is more than just affordable and reliable—it delivers powerful performance for industrial use. Below are some of its key features:

| Feature | Specification |

|---|---|

| Print Height | Up to 72 mm |

| Print Speed | 90 m/min at 100 dpi, 60 m/min at 180 dpi |

| Resolution | Up to 180 dpi |

| Print Length | Messages up to 4,600 mm |

| Throw Distance | Up to 15 mm |

| Ink Variety | Red, blue, black, pigmented white/yellow, UV black/white |

| Drying Time | 10–15 seconds on non-porous surfaces |

| Memory | Stores over 1,000 messages |

| Connectivity | Ethernet, USB, RS-232, photocell, encoder |

| Controller | 7″ LCD touch screen |

These specs enable the RNJet 72 to adapt to high-speed lines while printing complex or long-format codes clearly and consistently.

Ink Versatility for Any Surface

Pallets come in all shapes, sizes, and finishes. The RNJet 72 handles them all. Whether your pallets are made of raw wood, coated wood, chipboard, or plastic, this printer delivers strong adhesion and high contrast.

- Solvent-based ink: Perfect for non-porous or semi-porous materials.

- Oil-based ink: Great for porous surfaces like untreated wood or fiberboard.

- Pigmented and UV inks: Allow for high-visibility, high-durability markings on dark materials or for covert coding.

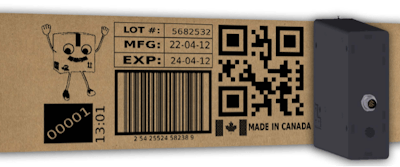

The result? Sharp, smudge-free prints that are legible and long-lasting—no matter the surface.

Real-World Application: Pallet Marking Made Easy

Let’s consider a real-world example. A wood packaging facility processes hundreds of pallets per hour. Each pallet needs:

- A company logo

- An IPPC certification code

- A batch ID

With the RNJet 72:

- The printer queues up designs and prints them at 90 m/min with zero smudging.

- No operator intervention is required beyond occasional ink cartridge changes.

The outcome? Faster production, reduced costs, and improved accuracy—all from one system.

Conclusion: Power, Simplicity, and Reliability in One

The RNJet 72 isn’t just a printer—it’s a production asset. With its high-speed capabilities, versatile ink system, and maintenance-free reliability, it brings unmatched value to any pallet marking process.

By investing in a system like this, you gain not only a tool for printing but a scalable platform for traceable, cost-effective, and consistent pallet identification.