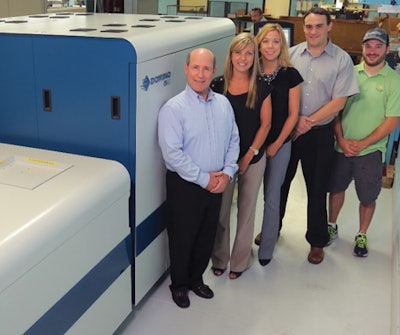

The Domino N610i digital UV inkjet label press has been a big win for this innovative label company that continues to reinvent itself through the decades. In a short time, McCourt Label has already seen an increase in sales due to the ability to capture new types of label jobs they could not economically produce before. They are also seeing significant productivity gains and higher print quality on existing jobs.

“We have a new customer who has 228 SKUs of their product, and that’s an example of a job where we would not have stood a chance of being competitive printing it flexo, but now with the Domino, it got us in the door,” says Sharon Zampogna, VP of Sales, McCourt Label. “If we had produced that using four-color process, it would have been at least 800 flexo plates.”

Dave Ferguson, President of McCourt Label, has noticed a significant increase in productivity and cost savings. An example is a print job involving 1600 different customers with a couple different label sizes and materials for an outdoor application printing on clear film. “Scrap and labor savings since moving this job to the Domino is huge. With the Domino we can run in one hour what we used to run in an entire shift on flexo,” he says.

McCourt Label undertook a thorough and rigorous five-year vetting process for selecting this, their very first, digital label press. “The reason we selected the Domino N610i was because of the requirements that we have for very high quality printing on clear film and other substrates. The trials on the Domino were superior to what their competitors could show us. And the print speed was superior,” says Ferguson. Zampogna agrees. “From a sales perspective, or an estimating perspective, what I liked was the flexibility. There was no blanket size that we had to fill. There was a wide variety of materials that we could run through the Domino. We do a lot of work in manufacturing, so we liked the idea of the UV ink and that the print quality is highly durable.” Click here to learn more about McCourt Label’s experience with the N610i.