ScottsMiracle-Gro has introduced its new O.M. Scott & Sons line, featuring natural grass food, grass seed, and clover seed, with a focus on sustainability from the inside out. The products use natural, pet-safe ingredients and are packaged in curbside-recyclable paper bags designed to appeal to younger consumers looking for eco-friendly options in lawn care.

The new line is inspired by company founder Orlando McLean Scott, a Civil War veteran who, in 1868, began selling weed-free grass seed in Marysville, Ohio. That same town remains home to The Scotts Miracle-Gro Company today. The brand revival celebrates Scotts’ 160-year heritage while responding to modern demands for transparency, natural ingredients, and packaging that’s easy on the planet.

“This is the perfect product form for consumers who care about sustainability but still want their yards to perform,” says Ray Severa, manager of Packaging & Applicators at ScottsMiracle-Gro.

The natural lawn food delivers slow-release nutrients without synthetic additives, and the grass seed varieties are drought- and heat-tolerant, with clover offered as a low-maintenance alternative to traditional turf.

| Read this related article on another Scotts packaging innovation at “ScottsMiracle-Gro Debuts New Refill Format for Lawn-Care Concentrates” |

To match the natural profile of the products, Scotts worked with ProAmpac to develop a recyclable kraft open-mouth SOS (self-opening sack) made from more than 90% FSC-certified paper, with an “ultra, ultra-thin OPP [oriented polypropylene] liner,” as Severa describes it. The liner, which measures five ten-thousands of an inch—a fifth of the thickness of copy paper—provides light moisture resistance. “A lot of CPGs still use more barrier than they really need,” Severa says. “We designed this bag to be just enough—no more, no less—so that it performs while still being easy to recycle.”

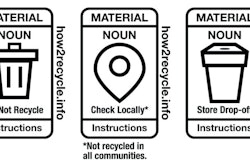

Despite the plastic layer, the bag meets the 85% pulp recovery threshold for curbside recyclability and has been certified by Western Michigan University. It also carries the How2Recycle “widely recyclable” label, helping consumers easily identify it as recyclable.

The bag uses a double fold-over seal, a common closure in the pet food industry, and is decorated with low-coverage, water-based inks and minimal adhesives to preserve recyclability. Visually, the design leans on the brand’s heritage with a muted color palette and the revived O.M. Scott logo, reinforcing the product’s natural positioning. “Anytime people see kraft paper, they instinctively think of sustainability,” Severa says. “That helps reinforce the message before they even read the label.”

To validate performance, Scotts subjected the bags to accelerated aging tests and outdoor exposure through fall and winter in Ohio. “We even left these bags outside during months of cold and wet weather,” Severa shares. “The product inside remained flowable and still germinated. That told us we had something durable enough for real-world conditions.”

Currently, the bags are being filled using a semi-manual process, though sealing is already automated using equipment adapted from high-speed pet food lines. “We’re running the new line at about half the speed of our traditional plastic bag lines,” Severa notes. “That’s fast enough to get to market quickly, and we’ll scale up if it performs.”

The paper bag platform also positions Scotts for future refill applications across its product portfolio. Severa cites opportunities to pair the bags with durable containers, such as those used for Miracle-Gro’s Shake ’N Feed all-purpose plant food. “Refill strategies are a win for both sustainability and cost,” he says. “As EPR legislation ramps up, these kinds of formats make more and more sense.”

| Read about another recent brand that has embraced pauperization in this article, “Mars' Kind is Next in Line with Curbside Recyclable Paper Wrapper” |

Beyond functionality and sustainability, Severa emphasizes the intuitive recyclability of paper. “Paper is recycled at about four times the rate of plastic in the U.S.,” he says. “The infrastructure is there, it’s been around since the 1960s, and it can handle small amounts of adhesives or plastic without issue. That’s a big part of why this format works.”

The bag is believed to be the only one of its kind in the category currently. The O.M. Scott & Son’s line is now available online through Amazon and Scotts.com. Retail placement is under review for future seasons. “We’ve already had strong interest from retailers and trade partners such as Home Depot and Lowe’s,” Severa says. “This platform checks all the boxes—performance, sustainability, and consumer relevance.” PW