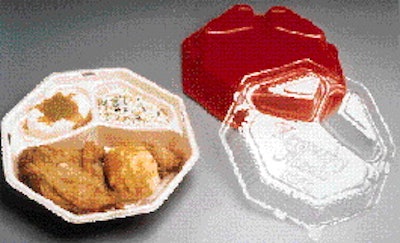

But even before the results of the test are in, the package has its share of admirers. It won a Worldstar for Packaging award in the Retail-Foodservice category from the World Packaging Organisation. Produced by Genpak (Glens Falls, NY), the KFC award winner is a tray/lid combination whose design patent is jointly shared by KFC and Genpak. The tray is a two-layer structure that Genpak makes by first extruding expanded polystyrene foam. Then, in the same pass, a 2-mil layer of high-impact polystyrene is extruded onto the 70-mil EPS. Next is thermoforming, in a separate operation, into a three-compartment, 2"-deep tray with the foam on the inside to keep food at the right temperature and the HIPS on the outside to provide a glossy, attractive, KFC-red appearance. Genpak's Ed Rider claims the two-layer tray is commercial in Europe but that this represents the first use of it in the U.S. One of the key challenges, he adds, is figuring out what to do with the trim scrap. Genpak has apparently solved that problem, and Rider says the trays it makes for KFC have reprocessed scrap in them, but he chooses not to elaborate on just how it's done. Completing the new packaging concept is a clear dome of polyethylene terephthalate. It's thermoformed by Genpak from sheet that is 15 mils thick. Genpak also extrudes the sheet for the domes, using Eastman (Kingsport, TN) PET resin. In the trim press that cuts individual domes from the sheet after thermoforming, vents are punched into the area that will be used over the chicken. This lets steam escape so that coatings on the chicken won't get soggy. An intriguing feature of the dome/tray combo is the way the two fit together to prevent leakage of sauces or juices from one compartment to another. A small channel nearly 1/4" deep formed in the walls of each of the tray's compartments mates with a formed ridge on the walls of the dome. When restaurant workers apply dome to tray, these formed parts compress in a male/ female fashion, thus securely segregating food in each compartment.