Radio-frequency identification systems developer Franwell and middleware vendor GlobeRanger have teamed with the Danby Group, a supply chain systems integrator, to implement an RFID compliance solution at Beaver Street Fisheries. BSF, Jacksonville, FL, is one of the nation's largest distributors of frozen seafood and meat.

Following qualification testing, BFS selected printer-encoders from Zebra Technologies. BSF’s arrangement includes a pilot line in the facility that uses a Zebra R110XiIIIPlus unit and a test lab using Zebra Z4MPlus and R4MPlus units. The units affix a 4’’x6’’ pressure-sensitive “smart label” to the side of corrugated cases. The labels must withstand the rigors of frozen handling and distribution. Among other details, RFID Antenna has learned that the tags are embedded with Matrics Class 0+ RFID tags.

The solution is built on GlobeRanger’s iMotion™ Edgeware™ platform.

“After conducting several RFID pilots, we selected Franwell’s rfid>Genesis package to help us rapidly deploy a proven solution,” says Howard Stockdale, chief information officer of BSF. “We are the only frozen seafood company that volunteered to meet Wal-Mart’s compliance requirements by January of 2005.”

Highly challenging

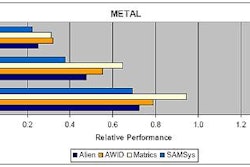

“Frozen seafood is extraordinarily challenging for RFID,” says Danby salesman Rich Bruce. “Though ice is RF transparent, frozen fish acts like a metal plate. Each species is different. Shellfish is as different from fish as squash and apples are in produce applications.”

The Zebra printer-encoder operation in the plant consists of the following process:

1. Receives Electronic Product Code print information and programs that to the RFID tag portion of the smart label.

2. Verifies that the data is correct and the tag is working properly.

3. Prints human-readable information such as bar code and other data

4. Dispenses label for application onto the case

BSF’s initial implementation phase includes setting up compliance stations where RFID labels are encoded using a Zebra R110 smart label printer-encoder and applied to corrugated cases of tilapia, crab, lobster, and other frozen fish products. Cases are then validated through a RFID portal. The company packages more than 500 different items.

Plans and lessons

BSF’s long-term RFID vision is to involve its network of suppliers to apply RFID labels at the source and leverage information on the RFID tags to meet legal data requirements such as method of catch, catch weight, country of origin, and date codes. That’s quite an undertaking--BSF receives products from 50 different countries.

Asked about lessons learned, Matt Ream, Zebra’s senior manager RFID systems, replies, “it’s that frozen fish can be RFID tagged and tracked, which was a big question when we went into this application. In fact, this is one of the first frozen foods applications for RFID we’ve worked on.” Zebra had previously worked with BFS in conventional case labeling. Ream says that there are a lot of companies facing Wal-Mart’s January 1, 2005 deadline for RFID that haven’t even purchased equipment yet for their RFID deployment. “Meanwhile, Beaver Street Fisheries is close to going live,” he adds.