This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

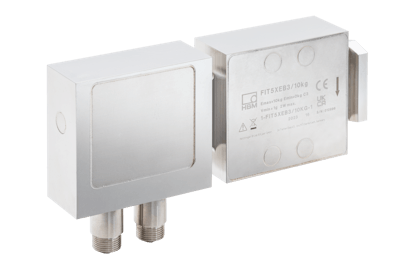

Hottinger Brüel & Kjær, the union of HBM and Brüel & Kjær, announces the launch of the latest innovation in weighing—the FIT5X digital load cell, specifically designed to revolutionize the control of the packaging process for manufacturers of rotary filling/dosing machines.

Cutting-edge digital control: The FIT5X surpasses the limitations of legacy single-point or analogue load cells. It emerges as an advanced digital load cell, merging a sophisticated filling/dosing algorithm with a control weighing function. Manufacturers now can benefit from advanced automation and increased precision in the filling process.

Intelligent interaction: Thanks to its digital inputs/outputs, the FIT5X provides intelligent interaction with triggers/actuators such as valves, paving the way for unparalleled automated process control. This feature allows manufacturers to optimize operations, improve the consistency of finished products, and ensure maximum yield from their rotary filling/dosing machines.

Evolution from FIT5A: As an evolution of the FIT5A, the FIT5X brings crucial additional advantages. Its hermetically sealed construction, even in the sensing area, eliminates risks associated with external exposure, minimizing contaminant accumulations and avoiding zero-point or linearity issues.

Simplicity and reliability: The FIT5X design emphasizes simplicity and reliability. The absence of complex mechanical structures exposed externally, significantly reduces the risks of errors related to contaminant accumulation. This ensures not only consistent quality of finished products but also contributes to extending the operational life of the machine.

The choice for Industry 4.0: In the context of Industry 4.0, the FIT5X stands out as an attractive option for manufacturers of rotary filling/dosing machines looking to stay at the forefront of innovation. Its seamless integration with digital technologies, combined with its advanced features, positions manufacturers to meet the changing market demands.