This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Regal Rexnord Corporation, a global expert in the engineering and manufacturing of electric motors and controls, power generation products, and power transmission components, will showcase motion control and powertrain solutions that help customers achieve sustainable productivity and overcome common operational challenges for the material handling, packaging, food and beverage industries at PACK EXPO 2025, Booth North Hall N-8814. The show takes place in Las Vegas from September 29 to October 1.

With increased consumer demand driving the need for warehouses and fulfillment centers to send more products out the door at faster speeds, delivering sustainable productivity is a key goal of operation teams. However, many challenges can hinder optimal throughput and lead to increased downtime. These include frequent maintenance, line malfunctions, workforce retention, changeovers, and the complexity of integrating new components and systems.

Perceptiv Gateway with SensorRegal Rexnord

Perceptiv Gateway with SensorRegal Rexnord

At PACK EXPO, Regal Rexnord’s material handling and packaging experts will highlight how customers can implement customized, end-to-end powertrain solutions to address these exact challenges and increase overall equipment effectiveness. These solutions leverage decades of united engineering expertise and innovative products from a portfolio of best-in-class brands.

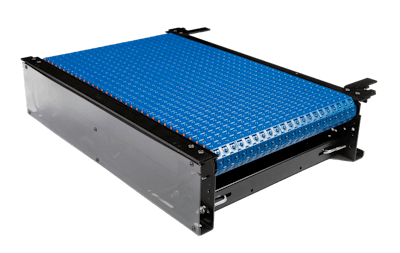

● Improve facility and operation performance by incorporating integrated solutions leveraging our ModSort® Divert and Transfer Modules for factory automation.

● Reduce downtime and increase productivity with our new IIoT connected conveyors, powered by Perceptiv™ Intelligent Reliability Solutions. Start or enhance your condition monitoring and predictive maintenance journey with our cost effective “smart” conveying package.

● Increase reliability with the Kollmorgen™ AKMH and AKMA servo motors featuring IP69K-rated washdown-ready construction, built specifically for durability, cleanability, and versatility. These high-performance motors paired with our IP67 distributed drives and vented cables are ideal for food and beverage environments, helping OEMs build machines that are cleaner, safer, and more reliable.

● Increase productivity and improve product handling for a variety of packages with the PriorityPal® High Level Case Palletizer. The modular layout runs up to 10 layers per minute and easily switches patterns using our interactive HMI system, allowing the user to choose from 50 preprogrammed patterns.

● Boost productivity for various robotic functions with the Movotrak™ Cobot Transfer Unit (CTU), which is the first-ever collaborative 7th axis that features collision detection settings for groundbreaking programming and control benefits. The Movotrak CTU adds a horizontal operating range of up to 10 meters and offers flexible mounting options.

● Enhance product handling and throughput with solutions such as our Rexnord™ conveying chains, Sealmaster™ Mounted Ball Bearings, McGill™ Cam Follower Bearings, Rex™ Roller Chain and Leaf Chain, and products from Formsprag™, Warner Electric™, and more.

While in the booth, experience the world record-breaking Rubik’s Cube-solving robot, developed by Purdue University students and powered by the Kollmorgen 2G Motion System. Solving the cube in just 0.103 seconds, this demo highlights the unmatched speed, precision, and synchronization of our AKM2G servo motors, AKD2G drives, and PCMM2G controller. Additionally, a large-scale conveying loop will provide visitors with a live demonstration of our powertrain solution and the Movotrak CTU.

Get more information about what Regal Rexnord will be showcasing at PACK EXPO 2025.