This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

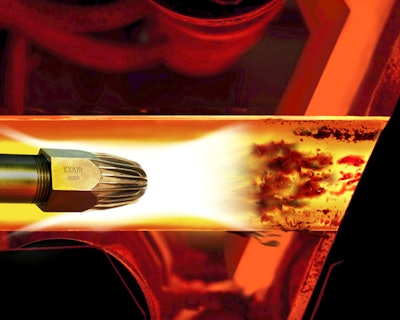

EXAIR's new 1 NPT Stainless Steel Super Air Nozzle™ delivers 6.6 pounds of strong blowing force for blowoff, cooling and drying applications located in corrosive, high temperature, food and pharmaceutical environments. Because the force is more than 8 times that of ordinary air nozzles, it is ideal for blowing heavy materials and where the air nozzle can’t be mounted close to the target surface. The aerodynamic design of the 1 NPT Stainless Steel Super Air Nozzle directs compressed air to a single point of convergence, delivering a concentrated stream of high velocity airflow with hard-hitting force. Safe operation is assured since the airflow cannot be blocked (as required by OSHA standard 29 CFR 1910.242(b)). At 80 PSIG, the air consumption is 135 SCFM and the sound level is 99 dBA, meeting the OSHA standard for 2 hours of use per day without hearing protection. The Type 316 stainless steel construction of this Super Air Nozzle has a 1-1/2" (38mm) hex body for easy installation using a standard wrench or socket. Applications include ejection of heavy parts, drying, part and machinery cleaning, chip removal, liquid blowoff, and cooling hot parts. For more information contact: EXAIR Corporation 11510 Goldcoast Dr. Cincinnati, OH 45249-1621 Phone: (800) 903-9247 Fax: (513) 671-3363 E-mail: [email protected] www.exair.com/52/1114SS.htm