The VersaSafe distributed safety system provides a TÜV-certified SIL3 machine safety solution that focuses on the critical control requirements of the production environment: safe operation and greater uptime of manufacturing equipment. High availability is delivered by integrating PROFINET with optional media redundant protocol (MRP) and multiple cable media options. Machine repair times are reduced by the ability to put a machine in a safe state without fully powering down the equipment, which, in turn enables faster start-up after a repair.

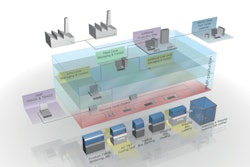

Leveraging PACSystems’ distributed I/O architecture and single point of connect capabilities, VersaSafe enables efficient development of high-performance modular machines. A single network carries standard and safety I/O; this simplifies wiring without compromising safety.

To minimize engineering efforts, GE provides a comprehensive set of tools and services as part of the VersaSafe solution, including a library of certified safety function blocks, the ability to seamlessly integrate safety and standard capabilities, and a robust set of integrated development and commissioning diagnostic utilities.

With VersaSafe, the need for a separate safety CPU has been eliminated, enabling a highly-distributed safety I/O configuration that is both cost effective and maintains high levels of performance as the system grows.

In addition, companies can make online changes to safety logic. Large production lines, in particular, will realize considerable benefit in the ability to update a portion of the safety logic without stopping the controller. Smaller machines benefit from right-sizing the safety I/O needs without bearing the overhead of a separate safety controller.

Available for new and retrofit applications.