The area sensing provided by the F77 series is also useful in applications where the pin-point accuracy of a photoelectric beam is too focused to accurately sense the target. These sensors are also highly immune to acoustic interference and have minimal deadband--important attributes for sensors mounted on machinery that uses numerous pneumatic cylinders.

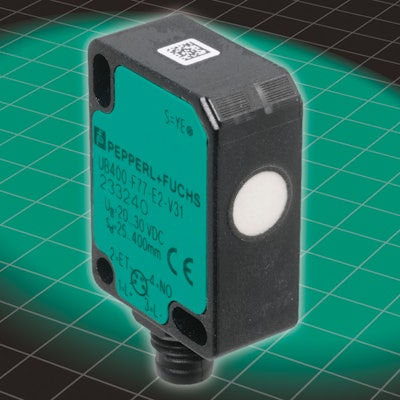

With a tiny 31mm x 11mm x 23mm housing, the sensors fit in space-restricted applications and provide up to 50 Hz switching frequency for fast response times. High visibility LEDs provide users with at-a-glance status indication, and simple, intuitive range adjustments make it easy to adapt to changing needs on-the-fly. These IP67 rated sensors are rated for use in temperatures ranging from -25…70 degrees C (-14…158 degrees F). A 4-pin Nano-style M8 connector makes installation easy. These sensors provide one PNP, N.O. (normally open) or N.C. (normally closed) switch point output, use inexpensive discrete PLC inputs, offer high or low frequency options and deliver a 2 Hz/mm maximum resolution. They are available in diffuse (up to 400 mm sensing range), retroreflective (up to 400 mm sensing range) and thru-beam models (up to 800 mm sensing range).