At a good trade show, a visitor can gain insights into developing trends by stopping at exhibitor stands, attending conferences and lectures, and mingling with colleagues and leaders of industry. Achema 2012 provided a futuristic perspective during its June 18 – 22 run at Frankfurt, Germany.

Achema is described as the world-leading forum of the process industry and the international trend-setting summit for chemical technology, environmental protection, and biotechnology. The event is organized by Dechema (www.dechema.de), a nonprofit scientific and technical society based in Frankfurt am Main, Germany. It has more than 5,500 private and institutional members, among them scientists, engineers, companies, organizations, and institutes. Dechema regards itself as an interface between science, economy, state, and the public.

During Achema, Dechema produced a series of trend reports that included the following insights compiled for the society by specialized international journalists:

Packaging as an additional security factor in protecting products and customers against pharmaceutical counterfeiting. “Intelligent brand protection systems can deter counterfeiters if imitation of the identification/marketing is made impossible or very costly. These technologies can also help clarify what is happening in the distribution and logistics chain and contribute to supply chain optimization.”

Modernization, flexibility, fast changeover, and minimal contamination risk are high on the priority list in today’s production environment. “If you think these factors through from the small scale to their logical conclusion, you almost inevitably arrive at the concept of single-use technologies.

“The latest generation of biotherapeutics will have a decisive influence on the future development of single-use technology. Compared to established manufacturing techniques for protein therapeutics, cell therapy is still in its infancy. Innovative equipment and new technologies will be absolutely essential for commercial success. Given the product requirements and the way the products are used, there is no alternative to single-use systems. More than 200 cell therapeutics for transplant medicine, cancer, and AIDS therapy are currently at the clinical trial stage. This is a great opportunity not only for the medical field, but also for single-use technologies.”

Patients benefit from biopharmaceuticals used in therapy and diagnostics. “Truly impressive results can be achieved with microbiological and biochemical technology. But they also show the long path from basic research to marketable products in therapy or diagnostics. We can expect to see a lot more exciting developments in the future.”

Plant engineering includes new approaches and partnerships, leaps in innovation. “Three years after the world economic crisis, there is plenty of work to do in the chemical plant engineering and construction sector. To improve the sustainability and energy efficiency of the facilities currently on the drawing board, the industry is not only building world-scale plants on green field sites, [but] also taking increasing advantage of integrated energy and raw material flows at chemical parks. Customized plant design remains the norm. Strategies for modular, container-size production are currently under development in the special chemicals sector.”

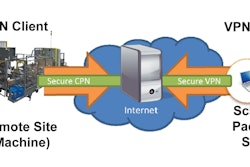

Automation systems create flexibility, intelligent production management. “The manufacturing industry needs a great deal of flexibility to stay in step with today’s market expectations. Automation engineering has taken on that challenge. Even out on the production floor, intelligent production management using tools such as lean production, production on demand, mass customization, global production management, and supply chain management is no longer feasible without intelligent, adaptive automation systems. Automation systems have become indispensable in many areas of our lives, and the development trajectory continues.”