Italy’s Cavanna Packaging Group specializes in the flowpack segment for both food and non-food products, especially for the cosmetics and pharmaceutical industries. The company was founded in 1960 in Italy’s Piedmont region as one of the first makers of electro-mechanical flow-pack machines. Over time, the family-owned company focused on fully electronic machines and complete packaging lines: primary flowpacks for individual products and product groups, secondary flowpacks or box packaging, and tertiary packaging in display cartons. Today, Cavanna has supplied roughly 6,000 machines for more than 900 customers worldwide.

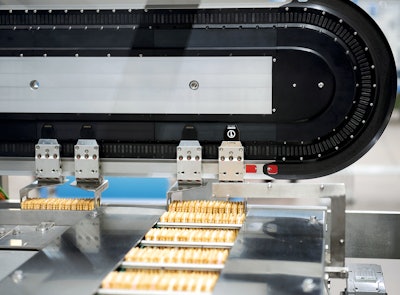

Recently, the OEM made the strategic decision to equip its flowpack machines with the intelligent eXtended Transport System (XTS) and EtherCAT communication technology from Beckhoff, starting with its cookie packaging segment.

The broad spectrum of food applications ranges from uniform and mixed cookie packages, chocolate, breakfast products, and sweet and salty snacks to bread replacement products, as well as cheese, coffee pods, and frozen products. Whatever the application, Cavanna focuses on protecting the product and maintaining the product quality through appropriate packaging, remembering that the consumer must also be able to open the package easily. The company’s engineering team considers all these requirements in the design of the flowpack machines in combination with high packaging quality, machine availability, and the lowest possible total cost of ownership (TOC).

The main objective of adopting XTS, according to Cavanna, was to improve its machines’ flexibility for product changeovers while reducing their footprint, time to market, and cost. The company also had to meet the rising requirements regarding gentle and efficient product handling. In the end, PC-based control from Beckhoff delivered the ideal control and drive solution. Cavanna also says it appreciated that Beckhoff prescribes to the same philosophy as the Italian company with its passion for quality, technological excellence, and reliability.

The technological innovation and continuous development of PC-based control were especially important for Cavanna because they enable the company to advance in accordance with changing customer requirements. An obvious example of this is the intelligent XTS transport system, which—in combination with the EtherCAT network—provides exceptional product transport flexibility in a very small space, the company says.