Many food manufacturers need traversing print heads integrated into the horizontal thermoform/fill/seal systems they operate. It’s an efficient way of delivering date codes and other variable data that might be required on the flexible film lidding material, regardless of the number of packs being produced across the machine direction.

Concept Solutions Inc. has developed just such a traversing print head system that can be integrated into any new or existing hf/f/s machine. It can utilize the ink-jet printing equipment from any one of a number of OEMs that make such equipment. What sets this coding solution apart from comparable ones is that it’s built of 300 Series stainless steel for duty in the harsh, caustic, wash-down environments so common in the food manufacturing business. Because it includes alloying elements such as chromium, manganese, and nickel, 300 Series stainless steel resists corrosion and is easy to sanitize.

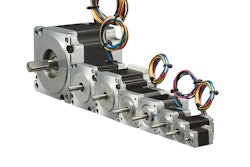

“Used more typically in such equipment is anodized aluminum,” says Brad Brower of Concept Solutions. “It holds up okay, but once you scratch it, it just won’t stand up to a caustic wash. As we looked at the marketplace, we did not see such a system made of stainless steel. So we made one. The servo motor, gear head, pulleys, and traverse rods on which the print head traverses are all stainless. The bearings are made of a special nonmetallic substance, and the drive belt is Kevlar reinforced.”

In addition to making it robust, every effort was made to also make it, as Brower says, “simple and scalable, without a lot of buttons to push. It takes longer to put the data in the printer than it does to put our traversing unit in action.”

The AKMH servo motor and the AquaTRUE planetary drive gearbox mentioned by Brower, both from Kollmorgen, are built to be cleaned with 2 to 12% solutions and exposed to 1450 psi spray without restriction. The AKMH servo motor has a two-year warranty against water ingress. An intuitive graphical HMI from Horner is used for set up. Simply load the start position, web width, and desired speed and then press go. All units are scaled automatically, eliminating the guess work from the setup, so typical commissioning time is 15 minutes or less and product changeover is accomplished in a matter of seconds.

Food manufacturers using form/fill/seal machines are definitely looking for something super durable and dependable when it comes to a traversing print head, says Brower. “Remember, these are packaging machines that come at the end of an upstream process of food preparation,” he points out. “If something goes wrong downstream from the food processing stage that prevents the food from being securely packaged in a container, you’re looking at a big-number cost to the business.”