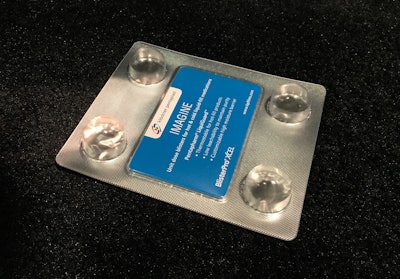

After three years of development, Klöckner Pentaplast debuted their LiquiGuard™ solution for packing liquid and semi-liquid doses today at Pack Expo. Their client needed a non-stick packaging solution that could resist high temperatures, prevent dehydration and agglomeration, retain flavor, and still be child resistant. The solution takes advantage of the inherent benefits of liquids by creating an easy to swallow/drink single dose that can be conveniently and discretely stored on a person. The packaging is easily customizable and can also aid in adherence.

Standard blister packs pose problems as they typically cannot withstand hot filling, they may interact with the product to alter flavor and appearance, and they may not be able to run economically. Working with their sponsors, Klöckner developed a multi-layered solution. They landed on a resin with high temperature resistance, controlled shrinkage, and low leachability. The barrier layer needed to be easy to thermoform, yet resilient enough to remain unaltered. They also needed to create new tooling and fabrication machines, filling techniques, and lid stock.