The contract packaging industry is in the early stages of a massive wave of consolidation that will reshape the marketplace. Within five years, the market will resemble financial services, waste management, retail, and the automotive industries; a handful of companies will assert leadership over the contract packaging industry, and the gap between the “haves” and “have nots” will expand significantly.

The core driver of this trend is the convergence of contract packaging and contract logistics. This convergence will accelerate as consumer packaged goods (CPG) companies seek to reduce their suppliers, as packaging and logistics companies seek to expand their scope of services, and as outside capital funnels resources to the most innovative companies.

CPG companies and retailers marketing their own store brands are watching this convergence with interest as they consolidate and simplify their supply chains. Kimberly-Clark and Nortel are among the companies shortening their supplier lists and looking for packagers that can provider a broader scope of services.

Already, the contract packaging industry is seeing early signs of this convergence. Recent mergers—such as Rock-Tenn and Alliance Packaging, Weyerhaeuser and Wilton Connor, Sonoco and Corrflex, and Exel and Power Packaging—illustrate how packaging companies have become acquisition targets. These combined entities, in turn, are competing for larger CPG company contracts that leverage their expanded scope. In May 2006, the merger of Wilpak with Jacobson Companies highlighted the value the market is placing on integrating supply chain leaders from contract packaging and contract logistics.

Who will be the winners? Who will be the losers? How can you ensure that you will be able to choose the right partners and control your destiny?

Contract packaging meets contract logistics

Historically, the contract packaging industry has contained three core segments. Primary packagers pack product directly. Secondary packagers perform value-added services like rework, export, customization, and specialized services. Display packagers pack primary packages into display units and combine trays or individual packages into display pallets. Merger activity in traditional packaging has been relatively modest, with paper and packaging companies like Sonoco seeking acquisitions of targets, such as Corrflex, in an effort to add complementary packaging services.

However, contract packaging is now beginning to merge with contract logistics. The term logistics was originally rooted in the military as a description of the services required to feed, arm, and supply troops. Today, logistics refers to warehousing, surface transportation, and freight-forwarding services. To reduce inventory, shorten delivery times, and pursue just-in-time business models, companies have increasingly made logistics a vital part of their strategies.

Contract logistics has been gaining in importance for the following reasons:

• Size. At $1 trillion, the logistics market is nearly seven times the size of the $142 billion packaging market. The outsourced logistics market, in turn, is nearly a $100 billion market, much larger than the $20 billion contract packaging market.

• Growth. Based on its analysis and interviews with leading outsourcers, BG Strategic Advisors believes the contract logistics market has been growing at 15% annually for the past 10 years, faster than the 10% growth rate of contract packaging. Faster growth is partly the result of lower penetration, because only 9% of the U.S. logistics market is outsourced, compared with 14% of the contract packaging market. Another factor in cost growth is the estimated 15% to 30% cost savings companies can gain from outsourcing logistics versus handling logistics “in house.”

• Scope. The supply chain encompasses a broad range of services, including sourcing, airfreight, ocean freight, trucking, rail service, warehousing, reverse logistics, supply chain technology, and a mix of other capabilities. Logistics companies can provide their customers with various services while gaining deeper points of integration with their customers. This scope makes logistics companies increasingly valuable compared with specialists that cover a narrower set of capabilities.

In turn, top logistics providers are expanding their value to customers by cutting costs, solving a broader set of challenges, and delivering seamless supply chains. Of particular importance to CPG companies are contract packagers that can integrate their services with contract logistics.

Mergers on the march

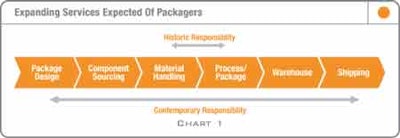

As CPG companies consolidate their supply chains, many leading-edge contract packagers are attempting to expand their scope of services to meet the customer need for integrated outsourcing services. Chart 1 highlights the new scope of services that CPG companies expect of contract packagers.

In addition, forward-thinking contract packagers have been seeking new ways to meet customer needs for integrated supply chains by joining forces with logistics companies. A prime example is Exel’s purchase of Power Packaging. Exel is a $7 billion global logistics company that expanded into contract manufacturing and packaging with its purchase of Power Group in 2006. In the process, Exel transformed itself from value-added warehousing into full-blown supply chain solutions.

Why was the Exel-Power merger so valuable? It provided the ability to combine warehousing, packaging, and supply chain services into an integrated solution to create value for CPG companies. It also enabled Exel to extend Power Packaging’s core skills and expertise in dry foods and beverages to products such as health and beauty aids, pharmaceuticals, and medical devices. Finally, it allowed Exel to improve its utilization of existing warehouse facilities while raising the revenue per square foot that the warehouse-based logistics giant could accomplish.

Buyers of contract packaging services at CPG companies who want to anticipate how convergence will affect contract packaging can look at similar industries to see how the trend is already reshaping the automotive and high-tech industries. In 2001, General Motors formed a joint venture with Menlo Logistics called Vector SCM (supply chain management). This $6 billion startup handles all of GM’s outsourced logistics, serving as the primary point of contact for dozens of 3PLs that once worked with GM directly.

GM’s motivation included the desire to slash its dealers’ car purchase and ordering cycles from 60 days to 15. These efficiencies are driven by a logistics technology platform known as “Vector Vision.” With this integrated system, GM sought to create a clearer view of its global logistics operations and a truly electronic supply chain.

By analyzing the GM example, some contract packagers are recognizing that integrated supply chain solutions require the ability to provide logistics and packaging services, as well as broad additional capabilities.

Logistics’ impact on packagers

As supply chain and outsourcing markets converge, logistics will disproportionately impact the packaging industry. Chart 2 shows the comparative market sizes of the packaging and logistics sectors.

As the data show, the contract logistics market is five to seven times the size of the contract packaging industry, and growing nearly 50% faster, at 15%. Further, logistics companies play a broader strategic role because of the range of supply chain solutions they can provide. These include warehousing, surface transportation, freight forwarding, and outsourced information technology. Consequently, integrated 3PLs also enjoy deeper strategic linkages with their customers.

Thus, due to larger size, faster growth, broader scope, and tighter integration, the logistics market wields disproportionate influence on its customers compared with the packaging sector and will exert a disproportionate impact in the coming convergence between contract packaging and contract logistics.

Increasingly, small contract-packaging companies that fail to add supply chain services to their mix will find themselves crowded out of the market. In turn, large logistics companies will try to combine packaging with warehousing to create more compelling supply chain solutions.

The ‘China effect’

These consolidation pressures will be intensified by the “China effect.” As the North American manufacturing base shifts to China, packaging companies will need to adjust to a new reality. Packagers will open locations in Asia, merge with companies that can control their customers’ supply chain spending in Asia, or lose customers.

Lowe’s offers a good example. When the home improvement giant shifted its manufacturing of private-label light fixtures to China, it moved its packaging operations there as well. In addition, the company outsourced paperboard cartons and corrugated cartons to China. As a result, packaging companies that were doing business with Lowe’s had to adapt or lose customers.

There is a silver lining within the China effect. Growth opportunities loom for packagers that forge relationships with Asia-based global freight forwarders, contract manufacturers, or supply chain-sourcing companies. Indeed, the fastest-growing companies in the global logistics landscape have focused on freight-forwarding services that link Asian production with U.S. consumption. Smart packaging companies can look to freight forwarders for a solution to the China effect.

Responding to the squeeze play

As merger and acquisition activities continue to accelerate in contract packaging, many companies are finding themselves squeezed. On the one hand, packaging materials companies are moving downstream into packaging services. Rock-Tenn’s acquisition of Alliance Packaging, Weyerhaeuser’s acquisition of Wilton Connor, and Sonoco’s acquisition of Corrflex all reflect the desire for paper-based companies to add packaging capabilities via merger. On the other hand, 3PL companies are moving upstream into packaging services. Exel’s acquisition of Power Packaging is a prime example of this trend. Chart 3 illustrates this “squeeze play.”

Wilpak’s recent merger with Jacobson Companies, Des Moines, IA, illustrates a third scenario, whereby companies can work strategically to broaden their services. Wilpak, an Atlanta, GA-based primary and secondary packager, provides major CPG companies with co-packing services and projects requiring site selection, engineering, design and development, information technology solutions, financing, and project management.

Jacobson is a national logistics provider, with operations in 17 states. The company provides warehousing, transportation, and logistics services and was seeking to strengthen its value-added capabilities in complementary categories.

The merger expands Wilpak’s core competencies from packaging into multiservice logistics, and broadens its geographic scope from Atlanta and Chicago to nationwide. Jacobson can now combine manufacturing, packaging, and supply chain services into an integrated suite that creates value for customers.

In summary, the smartest contract packaging companies are preparing for the coming wave of consolidation. As customers attempt to combine outsourced packaging with outsourced logistics, the result will be more combinations of:

• Packaging with paper manufacturers.

• Primary packaging with secondary packaging.

• Packaging with warehousing.

• Packaging with other outsourced supply chain services, such as global freight forwarding.

The growing crescendo of convergence activity is just the beginning of a trend. Whether as buyers, sellers, or niche providers, the leading packagers are staking out their positions in a rapidly changing marketplace. [CP]

Guide for the perplexed purchasing manager: What to look for in your co-packer

Amid this rapidly changing marketplace, how should purchasing managers respond? It is important that you choose a strategy—not by default but with clear goals and deliberate action.

When trying to determine how to select a co-packer, here are some questions to ask:

1. What is your scope of services? Can you help us not just with contract packaging but also with warehousing, logistics, and supply chain services? If you can’t, who are your partners that will provide these dimensions?

2. How broad is your geographic footprint? Can you help us with our national needs, or just a small region?

3. What is your financial viability? How strong is your balance sheet, and how fast are you growing?

Few companies today can integrate packaging, warehousing, and logistics services. However, as the industry evolves, more companies will opt for this route. Therefore, it is crucial to go beyond making vendor decisions based on price and service levels and anticipate the need for a broader set of solutions. A good Request for Proposal (RFP) will address all the above questions.

In addition, consider creative solutions to your packaging needs. Your warehousing supplier, for instance, may be a good candidate to help you with packaging. Alternatively, your co-packer may be able to provide warehousing.

Select a strategy: How Wilpak did it

How should co-packers and supply chain companies respond to the consolidating packaging marketplace? Wilpak shows how one contract packager answered this question.

In 2005, Wilpak CEO Eric Wilhelm reviewed his options.

Although Wilhelm was optimistic about Wilpak’s future, he also realized the company was resource-constrained relative to its growth potential and might miss out on future opportunities. Wilhelm and his strategic advisers considered three options:

1. Maintain the status quo. Wilpak was experiencing double-digit annual growth. By selecting this option, Wilpak could continue expanding without making major changes. But Wilhelm believed his company would benefit from adding scale.

2. Raise capital. Wilhelm considered bringing on a capital partner to fund aggressive growth. With a private equity investor, Wilpak could fund an acquisition, expand organically from its Atlanta base into the Midwest and West Coast, and gain national scale. However, Wilhelm estimated it would take up to three years to become a truly coast-to-coast packaging provider. He also worried that Wilpak would have to “go it alone” against warehousing-packaging-logistics combinations in a converging marketplace.

3. Merge with a national leader. Wilhelm opted to merge with Jacobson Companies. He concluded that to best meet his customers’ needs and provide multiservice, multilocation supply chain services, he had to join forces with a national logistics provider.

Three fundamental paths of action for co-packers

In a consolidating market, co-packers need to adopt one of three strategies.

First, the highest-quality contract packagers can serve as attractive merger candidates with logistics companies. Together, they can achieve the scale and scope needed to better meet CPG companies’ demand for a one-stop-shop supply chain.

Second, niche-oriented packagers may be able to survive through a narrow focus on difficult-to-serve specialty segments. For example, contract packagers with leadership in subcategories of food packaging, fast-moving consumer goods products, or other hard-to-replicate capabilities are well suited to adapt.

Third, packagers can choose to simply harvest their business. However, future growth will be harder to achieve and will carry lower margins.

The author, Benjamin Gordon, is managing director of BG Strategic Advisors Inc., a global investment banking and strategy consulting firm specializing in merger-and- acquisition advisory services for companies in the packaging, logistics, and supply chain sectors. Contact Benjamin at [email protected] or 561/655-6677.