Advanced skin and hair-care company Nécessaire “is recognized as a steward of responsible luxury, with the planet as its key stakeholder.” That’s according to the company’s vice president of supply chain, Michael Weinstein, who shares that Los Angeles-based Nécessaire uses its business to make a positive environmental impact everywhere it can. That includes finding ways to minimize its packaging footprint across production, shipping, and end-of-life impact.

Nécessaire’s product portfolio includes body and hair-care solutions formulated with clinical skin-care actives that deliver facial-grade efficacy “neck down.” All of its offerings are hypoallergenic, dermatologist-tested, non-comedogenic, and vegan. Among its sustainability credentials, the company is a Certified B Corp, a 1% For the Planet member, is Climate Neutral-, Plastic Neutral-, and FSC-Certified, and partners with How2Recycle to deliver verified recycling claims in the U.S. and Canada.

As is the case with most skin-care companies, product sampling is extremely important for Nécessaire’s business, as it allows consumers to test a product’s texture, scent, and effectiveness on their skin before committing to a full-sized purchase.

| Read this related article, “Aveda’s Recyclable Paper Sample Packet Replaces Multilayer Foil Sachets” |

“At Nécessaire, we deliver textures that optimize the delivery of the ingredients while also feeling comfortable on the skin—the way it feels matters,” says Weinstein. “As we grow our community and expand on the body-care ritual, we have been selective in developing sampling vehicles that allow us to share our formulas with a wider audience.”

Until recently, the company was using plastic tubes with 50% PCR for trial sizes of its body wash and body serum. In an effort to reduce its use of plastic, Necessaire switched to Arcade Beauty’s Paper Packette sachet, made from 63% paper. According to Arcade, it created the paper format as a recycle-ready alternative to its traditional multilayer Packette, made from two layers of plastic film and one of aluminum.

“Our goal was to aim for design to recycle readiness within the paper stream by reducing the amount of plastic,” explains Arcade Beauty Global CSR Director Claudie Guerin. “To achieve this, we needed to replace the plastic external layer with paper. Reduction of plastic was also a goal in and of itself, as it permits us to reduce CO2 emissions, with the replacement of the aluminum foil.”

Eliminating the aluminum was the main hurdle, as it provides barriers against moisture, oxygen, and light to protect the product inside. According to Arcade Beauty Marketing Director Lindsey Khosla, the company conducted a number of market compatibility tests on multiple barrier options to validate a sufficient alternative barrier. Once alternatives were identified, it conducted compatibility tests with customer products.

While Khosla doesn’t provide specifics on materials or suppliers, she shares that the Paper Packette is constructed of a paper laminate with a metallized barrier layer and a sealant. “The three-layer structure offers a similar structure to traditional packettes and allows speed to market for a paper offering.”

Another challenge in designing the new packaging was maintaining aesthetics and managing brand expectations, says Guerin. “This includes different opening experiences and print finishes, as well as material flexibility as it relates to machine operations,” she says. After testing various paper options, Arcade validated a coated paper that allows for rotogravure printing.

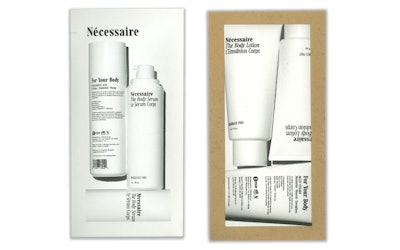

The stock solution is being used by Nécessaire for samples of The Body Lotion and The Body Serum. Arcade produces the material for the Paper Packette as rollstock, which it forms, fills, and seals for the skin and hair-care brand.

| Read another article that involves a switch to paper packaging in, “Biopolymer Coating Makes Paper Noodle Cup Compostable” |

While only recyclable in Spain, Finland, Sweden, and France, the Paper Packette shows significant environmental benefits versus a traditional multilayer, multi-material sachet used for sampling. To calculate the Paper Packette’s environmental impact across fossil fuel, GHGs, and water usage, Arcade used Trayak’s EcoImpact-Compass LCA software and industry standards for raw material, package manufacturing, transportation, and end-of-life disposal components. “Through this process, we learned that our 63% Paper Packette, when compared to a traditional foil structure, offers a 67% reduction in fossil fuel, a 69% reduction in CO2 emissions, and a 61% reduction in water usage,” shares Khosla.

Meanwhile, the company has conducted tests to develop a sachet with 80% paper content, but validating a material that is operational and has a sufficient barrier has been difficult, Guerin says. “Eighty percent paper is stiff and heavy, and many tested papers were not operational on production machines,” she says. “But the most challenging aspect of the development of the 80% Paper Packette is identifying a sufficient barrier. We had to identify a very lightweight barrier and sealant to maintain flexibility and hit the required paper percentage for recyclability. Many of these materials are not readily available from suppliers or fail to protect product bulk.”

Still, Nécessaire is pleased with its switch to the Paper Packette. Says Weinstein, “We shared the move to this 60%+ paper-based packette on our Instagram page, and the consumer feedback was positive.” PW