As EPR reporting ramps up, design teams are feeling the pressure to create packaging that doesn’t just perform, but also aligns with recovery systems and circularity goals. At the 2025 Packaging Recycling Summit in Dallas, a number of speakers shared how they’re refining materials, improving performance, and reducing environmental impacts across both primary and secondary packaging.

One material category that has been attracting growing attention is paper. Consumers overwhelmingly view paper as more sustainable, but its application in packaging design remains limited by performance barriers. “Honestly, it’s a dust cover,” said Guido Kollbach, business director, packaging adhesives at Henkel Corp. “It holds flour in the kitchen, and that’s about it.”

Guido Kollbach, business director, packaging adhesives for Henkel Corp.PMMI Media Group

Guido Kollbach, business director, packaging adhesives for Henkel Corp.PMMI Media Group

Unless enhanced with functional barriers, paper cannot withstand grease, moisture, or oxygen exposure, which makes it problematic for applications such as frozen foods, snacks, and liquids. To address this, Henkel has developed adhesive and coating systems that enable paper to take on properties traditionally delivered by plastic films or laminates. These barrier technologies help maintain freshness and shelf life while still allowing paper to be processed in fiber recovery systems.

“There’s no silver bullet,” Kollbach said. “But we have made big progress in combining functional performance and recyclability.” The goal is to replace complex multilayer structures with mono-material or recyclable alternatives without sacrificing the packaging’s role in product protection or user experience.

Ecoglogic Brands

Ecoglogic Brands

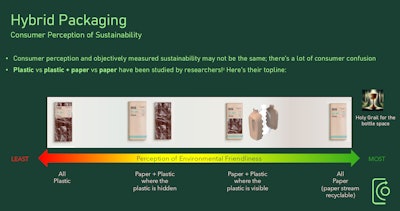

That balance between functionality and recyclability is also central to ongoing work at Ecologic Brands, a Jabil company. John Hursey, senior director, described how the company’s molded fiber bottle was designed to help move paper-based packaging closer to what he called the “holy grail.” In this case, that means a fiber-based structure that holds liquids or semi-liquids, reduces plastic use, and performs on par with traditional formats in terms of usability, shelf impact, and recyclability.

Ecologic’s solution features a rigid outer shell made from 100% recycled paper and a thin PET liner that is 70% lighter than standard HDPE. The two components can be separated by consumers and recycled in their respective material streams. “It’s a great story, if we can get consumers to separate the packaging,” Hursey said. If not separated, the overall plastic content is still far lower than a conventional plastic bottle.

| Read the related Annual Outlook Report on Sustainability, “Consumer Demand for Recyclability Leads to Paperization” |

While separation remains a hurdle, the hybrid format demonstrates a gradual approach to innovation. “It’s not going to be a revolution,” Hursey added. “It’s going to be an evolution. Every day, people like us are trying to make that better.”

Beyond the primary package, brands are also looking closely at upstream materials that never reach the consumer but still have a significant environmental footprint. One of the most impactful examples came from Marissa Lundberg, VP of national accounts, packaging and sustainability at Group O, who detailed a packaging redesign project with a major food manufacturer. The goal was to replace a virgin resin-based stretch film—already optimized by Group O for load stability and efficiency—with a version made from 30% PCR.

Group O

Group O

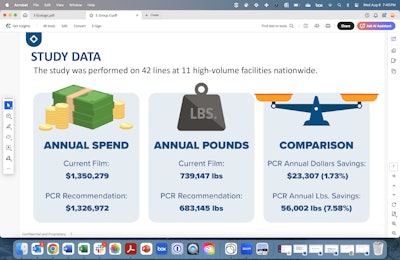

The team tested the PCR stretch film across 42 lines in 11 production facilities. Test conditions included a wide range of pallet loads, wrap patterns, film gauges, and equipment. Despite the change in material, the film maintained its performance and durability across all scenarios. “It actually outperformed expectations,” Lundberg said. “It was more consistent than we anticipated, even on older lines.”

The environmental benefits were significant. The switch resulted in a 21% reduction in CO2 emissions, 30% less fossil fuel use, and 30% less water consumption. These outcomes were modeled across the various plant locations and production volumes. Cost neutrality was also achieved, and in 10 of the 11 sites, the PCR film delivered savings compared to the virgin baseline. “This is a significant improvement, especially when you consider this one change implemented across multiple sites can dramatically reduce Scope 3 emissions at scale,” Lundberg said.

Importantly, the PCR film was compatible with existing post-use processes. The used stretch film could be baled, washed, and returned to resin form, creating a closed-loop system without requiring major changes in equipment or operations. PW