Refillable and reusable packaging is a growing trend in the Consumer Packaged Goods space, both for direct-to-consumer companies and for those large brands primarily selling their products at retail. Thus far, many of these products have followed the Refill-at-home model, with the majority comprising products in the household cleaning and personal care markets.

Less common in the Refill-at-home space are products that are ingested by the consumer, e.g., food and beverage and oral care products. But there are examples in these markets, as well. Not the first, but definitely the most recognizable brand to introduce a refillable/reusable packaging system in the oral care market is Listerine mouthwash from Johnson & Johnson Consumer Healthcare.

| Read this related article, “Reusable, Recyclable Glass Toothpaste Bottle is ‘Noice.’” |

Said to be another step toward the brand’s goal of “achieving healthier mouths on a healthier planet,” new Listerine Cool Mint Zero Alcohol Concentrate Refills in a 100-mL PET bottle are said to use 60% less plastic when compared to a standard 500-mL bottle of Listerine while providing the same benefits.

“Listerine is committed to helping people achieve the best oral care in a way that is responsible and more sustainable to help protect our planet,” says Jessica Snell, R&D director of Global Oral Health at J&J. “The Listerine Cool Mint Zero Alcohol Concentrate product was prioritized by Listerine’s scientists and packaging engineers, who worked to ensure that it met our rigorous standards for product safety, quality, and efficacy.”

Directions on how to use the new concentrate can be accessed via on-pack labeling, product description pages, the concentrate landing page, and Listerine’s social media platforms.

Directions on how to use the new concentrate can be accessed via on-pack labeling, product description pages, the concentrate landing page, and Listerine’s social media platforms.

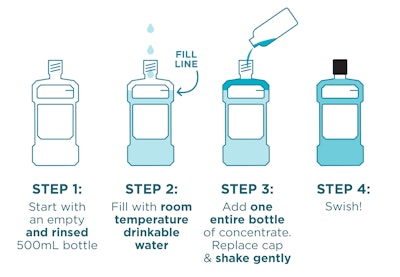

To tackle the challenge around changing consumer behavior, J&J says it is concentrating on education around product usage. “Our marketing and education for the product focuses on the four steps for diluting the concentrate to help consumers understand the new format,” says Lauren Wexler, head of marketing, Global Oral Care, J&J Consumer Health. “These steps can be accessed via on-pack labeling, product description pages, the concentrate landing page, and Listerine’s social media platforms.”

The four, simple steps are as follows: 1.) Start with an empty and rinsed 500-mL bottle; 2.) Fill with room temperature, drinkable water; 3.) Add one entire bottle of concentrate. Replace cap & shake gently; and 4.) Swish!

The packaging system was introduced in July 2022 and is available from Amazon.com, Walmart, Rite Aid, Walgreens, and Kroger. Options include a starter pack with a reusable bottle filled with mouthwash together with two concentrate refills or a three-count refill pack. Both options are packaged in a recyclable paperboard carton.

| Read the full article on Refill-at-home systems from which this story was taken, “Refill-at-Home Packaging Takes Off Across Categories.” |