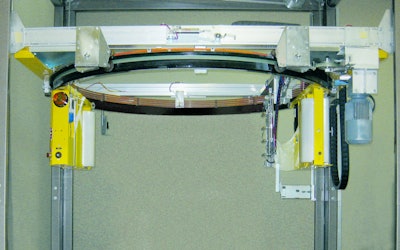

This automated feature eliminates one of the biggest sources of downtime- waiting for the operator to respond after a film issue. Because the Octopus can now run two rolls of film before needing attention, the operator only needs to address the machine half as often.

The SideKick is easy to maintain: it does not require an additional cut, clamp, or heat seal system. In addition, one carriage could be removed for maintenance while the second carriage continues to wrap. It is completely automatic, is designed with minimal moving parts, and does not add to the footprint of the machine.