New delta-style robots for the pick-and-pack line were already on order. The major American food producer’s equipment supplier, Langen Group, began designing the end-of-arm tool that would enable the Fanuc robots to pick up film-wrapped, stacked crackers and place them into corrugated cases. Then the engineers at Langen, a global supplier of product handling and packaging equipment, ran into a challenge.

To achieve maximum speed without upsetting the center of gravity of the robots, the tool—plus the weight of the product itself—couldn’t measure more than 2 kg. But the largest load of crackers on the line was 1.5 kg for a ten-pack. That meant the tool had to weigh less than 500 g.

Langen Group turned to Anubis 3D, a division of Anubis Manufacturing Consultants Corp., for support. Says Anubis president Tharwat Fouad, “Meeting these requirements would have been impossible with aluminum and sheet metal. To handle a heavier metal tool they’d have to reorder larger robots, which would have been more expensive—and they were also under extreme time constraints.” Furthermore, the tool needed to be quick-release and quick-connect, so operators could change from one size to another without bolts and nuts adding assembly time.

“There were different configurations, different shapes, and three case sizes,” says Fouad. “They wanted a single tool that could handle it all, weigh no more than half a kilo, and they wanted it as soon as possible.”

Additive manufacturing

Fouad knew exactly the technology that would provide the best solution: additive manufacturing (AM, or 3D printing). He had become increasingly familiar with the technology as his business grew. He started his engineering and design consultancy to serve the food and beverage, chemical, and powder handling industries in 2005, and he added a plastics manufacturing element in 2011. His Anubis 3D division specializes in low-volume production of parts that are either too expensive, too complex, or outright impossible to make through conventional manufacturing techniques.

Additive manufacturing became the clear choice for this specialization for a number of reasons. Fouad and his team first spent nine months studying the market, evaluating which manufacturing technology would best serve their customers. “We found that most of the manufacturers that bought into plastics-based AM did it for prototyping,” says Fouad. “But our reasons were completely different. We envisioned a number of opportunities for functional, end-use components, and we felt AM was the best technology for such applications.”

Once the decision to pursue AM was made, Fouad performed a detailed analysis of the many different types of equipment available before deciding on a FORMIGA P 100 system from EOS (www.eos.info.com). The system uses a 30-watt CO2 laser paired with precision optics to quickly and accurately “grow” parts measuring up to 200 mm x 250 mm x 330 mm (7.9 x 9.8 x 12 in) and layer thicknesses between 0.06 mm (0.0023 in) to 0.1 mm (0.0039 in), providing Anubis with the accuracy and size range needed to meet its customers’ demands.

Equally important to Fouad’s vision of end-use products was material selection—EOS powder-bed laser-sintering technology utilizes engineering-grade polyamides, polystyrenes, thermoplastic elastomers, and polyaryletherketones, for example. “The system gives us the ability to build a virtually endless array of parts, using materials that are widely accepted in the industry,” Fouad says. “Within a few days of delivery, EOS had us up and running. The system was quite easy to learn. Now, several years later, we remain very happy with our decision.”

Lighter yet more powerful

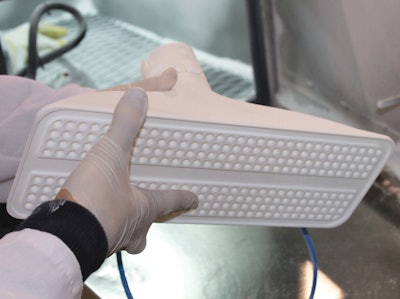

In the case of the robotic end-of-arm tooling for Langen Group, instead of a more traditional metal vacuum plate and shroud (which would have taken months to design and manufacture), Anubis designed a lighter, streamlined set of components that provided four times the gripping force of legacy vacuum grippers. It took only a week to additively manufacture, assemble, and test the new tool.

The material used for the main vacuum part was nylon 12 (PA 2200 material from EOS), chosen for its flexibility and ability to sustain crash loads, and because it is certified as USP Class VI approved for food contact. The wall thickness of the vacuum cup was between 2 and 3.5 mm and varied from section to section. The parts were designed specifically for AM with the help of a software program that optimizes the design of structures “organically,” following the lines of the geometry and adjusting the thickness as needed for strength and/or flexibility. Finite Element Analysis (FEA) is built into the optimization to analyze stresses and strains on the structure. “The creative part designs that AM allows still have to be fully functional,” says Fouad. “Many of the plastic products we make at Anubis replace aluminum and other metals, so care must be taken to assure structural integrity. We are completely confident that our additively manufactured plastic products will meet all customer requirements.”

Anubis loaded the material properties and vacuum requirements into the software, then used those calculations to determine how many and what size holes should be placed in the vacuum cup. The holes, laid out in a Swiss cheese pattern of channels leading to the primary vacuum hole at the top of the workpiece, create a superior grip on the cracker stacks. “The options we looked at were whether to have fewer, but larger, holes or more holes that were smaller,” says Fouad. First they duplicated the traditional aluminum plate hole layout using nylon 12 in the EOSINT P 395 system and tested the gripping power of the result. Then, to further increase the grip, the Anubis team created a new design with profiled holes and channels that could not have been manufactured conventionally. A larger number of these customized, smaller holes supplied a much stronger grab. Digital data from the final design guided the laser to melt the nylon and grow the parts in Anubis’ EOSINT P 395.

“The efficiency of the new hole profile we developed with EOS technology enabled the redesigned gripper to suction so well you could actually hang on it with your own weight,” says Fouad. “Our customer had never seen that level of performance before.”

The vacuum grippers were delivered to Langen Group and installed on the newly arrived robots at the food producer’s plant. “To design and produce tooling capable of picking what we wanted, while still staying within the pay load constraints of the robot, would have been impossible before,” says Langen Group Engineering Manager Robert Husnik. “Due to the freedom provided by plastics laser-sintering, we can now do the impossible.”

The additive manufacturing advantage

Achievements such as this are starting to become the norm in the additive manufacturing world. That’s because laser sintering has the ability to create organic shapes that are unimaginable with conventional manufacturing techniques. Complex internal structures, smooth curves and geometries, undercuts, and features that would be out of the reach of traditional tools—all this and more is achievable when parts are built one layer at a time.

“I tell people that, unlike traditional manufacturing, complexity is free with additive processes,” Fouad says. “A designer can come up with all sorts of wild ideas and no one will complain. You can reduce part weight, maintain strength, and deliver nice looking products with greater functionality, in less time, and at lower cost than ever before. It’s a real manufacturing shift.”

The biggest challenge to AM acceptance, Fouad says, is changing decades-old ways of thinking. “The conversion from metal to plastic is possible, especially when it’s done scientifically. You need to focus on part geometry, and throw out traditional concerns over part complexity. Laser sintering has no such constraints. Companies afraid of change often contact us only when they’ve run out of options. However, there are many, many times when laser-sintered parts are a better alternative to CNC, one that can reduce costs and deliver a better end product, and do so without any investments in tooling.”