Although Stonyfield Farm believes source reduction is the best way to minimize the burden of its packaging on the environment, the yogurt maker hasn’t abandoned reuse and recycling. In fact, for those two “Rs” the New Londonderry, NH, company is literally putting its money where its mouth is.

In 2000, for example, Stonyfield began a partnership with Recycline Inc. The Somerville, MA, firm markets toothbrushes whose bases are made primarily from post-consumer and post-industrial Stonyfield yogurt cup material. (Organisms are destroyed during post-grinding and reheating stages where the cup material reaches temperatures exceeding 350°F.)

Between mid-2000 and January 2002, more than 500ꯠ cups had been used to produce Recycline’s Preserve-brand toothbrushes. That’s according to Eric Hudson, Recycline’s president and chief executive officer. Hudson adds, “This year we’ll make about 600ꯠ toothbrushes and use almost one million cups” from Stonyfield. Toothbrushes are sold nationwide, at prices ranging between $3.29 and $3.95 at retailers such as Whole Foods, Wild Oats, and Trader Joe’s.

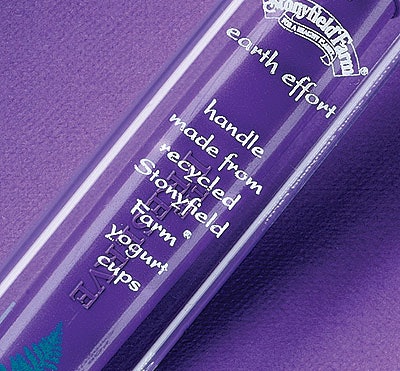

On one of the packaged Preserve toothbrushes (shown on opposite page) sent to Packaging World, a printed full-body band shows the Recycline and Stonyfield Farm logos, with copy that states “handle made from recycled Stonyfield Farm yogurt cups.” On a side panel, printed copy tells consumers, “Toothbrush and packaging are completely recyclable with Recycline’s postage-paid mailer. Send your used Preserve back to us—we turn them into plastic lumber, which is used to make porch decks and park benches.”

Stonyfield ships cup material to Recycline’s partner, a Massachusetts-based processor Hudson prefers not to name. Recycline works with advisors from the University of Massachusetts-Lowell to determine the specific formula so that the PP cup material will comprise 70% of the toothbrush handle. The processor combines those ingredients, melts, extrudes, and chops them into pellets. Pellets are injection-molded into the toothbrush handles by yet another undisclosed Recycline business partner.

“We collect cups from our visitors’ center next to our plant where consumers can buy our products, and from consumers who mail back empty polypropylene cups from yogurt they’ve purchased,” says Gary Hirshberg, Stonyfield’s chief executive officer. (The company doesn’t actively promote this plan, believing that more energy is used sending these back than is saved through recycling, but says many consumers do so because they believe they’re helping the environment.) The yogurt cup manufacturer and Stonyfield supply scrap material used to make the Recycline brush handles. “They pay for the transportation, and it’s a closed-loop program,” explains Stonyfield’s Nancy Hirshberg, vice president of natural resources.

Recycline’s Hudson says they’ve collected the cups at a local drop-off site as well. “We plan to continue to use as many cups from Stonyfield as we can get,” he says. Additionally, “we’re testing to see if we could use any polypropylene cup.”

Stonyfield and other “natural” product companies fit into Recycline’s business strategy. “We’re a consumer products company with a strong environmental bent,” relates Hudson. The company “was founded in 1996 in response to the growth of recycling and environmental concerns,” according to its www.recycline.com Web site. The site says, “Our primary goal is to develop and deliver to market quality product from recycled materials.”

See the story that goes with this sidebar: Analyze this